Describir

- Introducción

- ¿Qué hace? Fotosensor ¿Esencial para los sistemas modernos de alumbrado público?

- ¿Por qué las farolas exteriores Fotocontroladores ¿Fracasar prematuramente?

- Cómo elegir un proveedor confiable Control del sensor de luz ¿Para uso en exteriores?

- ¿Por qué se consideran las fotocélulas LONG-JOIN una solución fiable y de larga duración?

- Palabras finales

¿Notas que las luces de tu calle parpadean o dejan de funcionar demasiado pronto? A veces, interruptores de fotocélula Se averían demasiado pronto, a pesar de que parecen estar diseñados para durar. Estos pequeños dispositivos están pensados para mantener nuestras calles iluminadas de forma segura cada noche, pero muchos dejan de funcionar antes de lo previsto.

Desde condiciones climáticas adversas hasta cortes de energía inestables, múltiples factores pueden acortar su vida útil. Cuando esto sucede, aumentan los costos de mantenimiento y las calles de la ciudad se quedan a oscuras.

¿Cómo se pueden evitar estos fallos? Esta guía explica por qué. sensores de iluminación de fotocélula Si fracasa, también le ayudaremos a elegir una solución fiable y duradera para sistemas de iluminación exterior.

¿Qué hace? Fotosensor ¿Esencial para los sistemas modernos de alumbrado público?

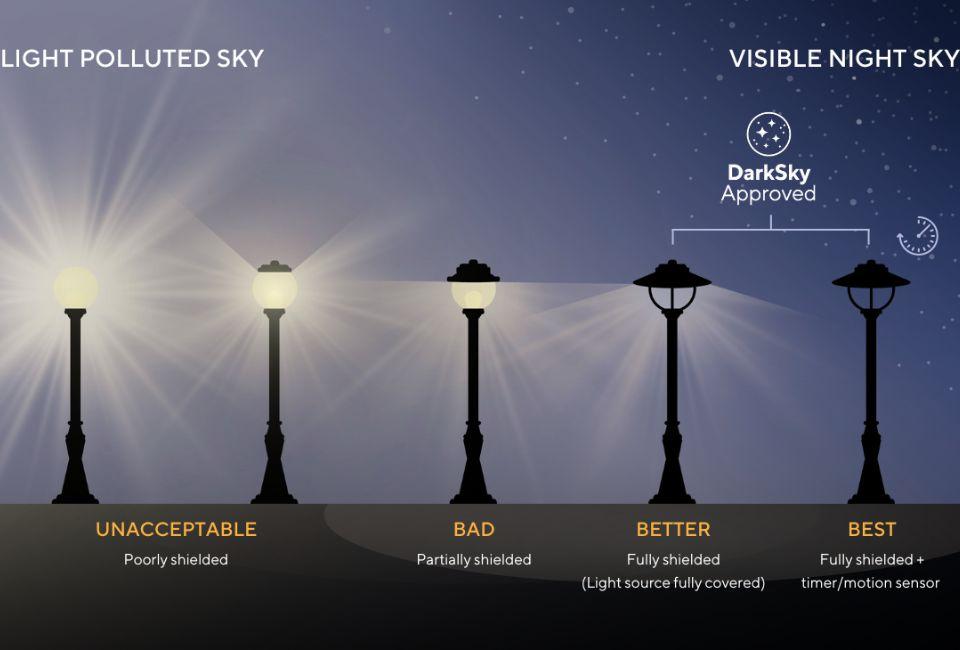

Controles de iluminación Detectan la luz ambiental y ajustan automáticamente el alumbrado público. Se encienden al anochecer y se apagan al amanecer. Esto sustituye el control manual.

Además, el sistema de conmutación automática mantiene la iluminación constante cuando es necesario y la detiene cuando no lo es. Esto ofrece múltiples ventajas, entre ellas:

- Reducción del consumo energético en los sistemas de iluminación exterior

- Garantiza una visibilidad segura para peatones y conductores.

- Mejora la eficiencia del sistema al adaptar la iluminación a las condiciones de brillo del mundo real.

En las redes de ciudades inteligentes, sensores de luz de fotocélula para exteriores Van más allá del simple control. Se conectan con sistemas IoT para el intercambio de datos, la operación remota y el control de la atenuación. Las ciudades pueden monitorizar y automatizar la iluminación en tiempo real. Esto contribuye a los objetivos de sostenibilidad y optimiza las operaciones en grandes infraestructuras urbanas.

¿Por qué las farolas exteriores Fotocontroladores ¿Fracasar prematuramente?

Las fallas en las fotocélulas aumentan los costos de mantenimiento, comprometen la seguridad y dañan la reputación. Un circuito de alumbrado público que no se enciende al anochecer o permanece encendido todo el día indica problemas más profundos. A continuación, exploramos las causas principales de las fallas prematuras y los indicadores a tener en cuenta.

Las duras condiciones ambientales exteriores afectan la vida útil de las fotocélulas

sensor fotoeléctrico se enfrenta a entornos extremos como:

- fluctuaciones de temperatura

- Exposición intensa a los rayos UV

- Lluvia Pesada

- Niebla salina; y

- Humedad

Cada condición acelera la degradación de la carcasa y la corrosión interna. Las carcasas deben utilizar un polímero resistente a los rayos UV. Las juntas deben estar selladas. Por último, la alta Clasificaciones IP Son imprescindibles para evitar la entrada de humedad y los daños causados por la sal.

Las sobretensiones eléctricas influyen en el fallo de las fotocélulas.

Las sobretensiones imponen altas corrientes y tensiones en los circuitos de las fotocélulas. Estos transitorios pueden quemar los relés o degradar los sensores.

Eficaz sensores de fotocélula de anochecer a amanecer incluir MOV (Varistor de óxido metálico) protección con clasificación de ~10 kA/20 kV o superior, para limitar las sobretensiones y preservar los componentes electrónicos internos.

Componentes de baja calidad

Los relés baratos, los plásticos de baja calidad y un sellado deficiente reducen drásticamente la vida útil. Un estudio informó que las fotocélulas fallaban, quedándose atascadas en modo de encendido/apagado, o presentaban filtraciones de agua en cuestión de meses. A lo largo de la vida útil del sistema, esto conlleva altos costos de reemplazo y mano de obra, lo que anula los beneficios de ahorro energético de la iluminación automatizada.

Importancia de la tecnología de conmutación por cruce por cero

La conmutación en momentos de máxima corriente o tensión somete a los relés a un esfuerzo excesivo y genera arcos eléctricos. Esto reduce la vida útil de los contactos y aumenta el estrés térmico.

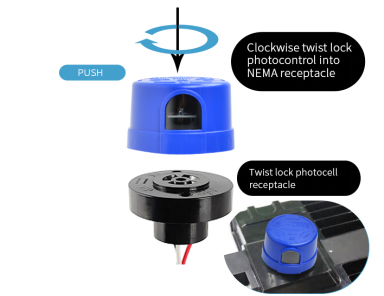

La tecnología de cruce por cero garantiza que la conmutación se produzca en el punto de tensión cero de la forma de onda de CA. Esto minimiza la corriente de arranque, lo que en última instancia prolonga la vida útil del receptáculo de fotocontrol y controlador de lámpara.

Una instalación incorrecta o una incompatibilidad provocan un mal funcionamiento.

Esta podría ser una razón importante. Algunos problemas comunes son:

- Instalar el sensor donde esté expuesto a luz artificial o reflejos → detección errónea.

- Errores de cableado o uso de una fotocélula incompatible con ciertas cargas de lámparas (por ejemplo, controlador LED frente a balasto HID) → sobrecalentamiento o mal funcionamiento.

Cómo elegir un proveedor confiable Control del sensor de luz ¿Para uso en exteriores?

Para evitar fallos en las fotocélulas, evalúe criterios técnicos y de especificación exigentes antes de la compra.

Las certificaciones garantizan la calidad

Elija fotocélulas certificadas según estándares internacionales. Estos incluyen:

- UL 773

- Norma ANSI C136.10

- Libro Zhaga 18 o Zhaga-D4i

El cumplimiento de estas normativas garantiza la intercambiabilidad de los enchufes y la compatibilidad con nodos inteligentes. Los productos certificados también simplifican su aceptación en el mercado global y facilitan las reclamaciones de garantía. La tabla siguiente resume las principales normas y su importancia en el control de la iluminación exterior.

| Estándar | Región de reconocimiento | Enfoque central |

| UL773 | América del norte | Fotocontroles para iluminación |

| Norma ANSI C136.10 | América del norte | Diseño de interfaz de bloqueo por giro |

| Libro Zhaga 18 | Global | interfaces de iluminación modulares |

| IEC 60529 (Clasificación IP) | Global | Protección contra la entrada |

| ISO 9001 | Global | sistema de gestión de la calidad |

Materiales que ofrecen la mejor resistencia ambiental

El material de fabricación es fundamental para la vida útil de un sensor de fotocélula de luz. Asegúrese de que las unidades estén fabricadas con tereftalato de polibutileno. Su cúpula debe ser de policarbonato estabilizado contra los rayos UV para mayor resistencia al calor. Su carcasa debe cumplir con la clasificación IP65 o IP66 y superar la prueba de niebla salina. Por último, las pruebas de envejecimiento por rayos UV y de humedad son cruciales para condiciones exteriores adversas.

A continuación se muestra una tabla con los materiales que se utilizan habitualmente en las fotocélulas de alta gama y sus funciones protectoras.

| Material | Función | Resistencia ambiental |

| PBT (tereftalato de polibutileno) | Material base estructural | Alta estabilidad térmica y resistencia a la corrosión |

| Policarbonato estabilizado a los rayos UV | Cubierta de cúpula transparente | Previene el amarilleamiento y el agrietamiento bajo la luz solar |

| Junta de silicona | Sellado e impermeabilización | Resiste temperaturas y humedad extremas |

| Tornillos de acero inoxidable | Componentes de fijación | Resistente a la corrosión y la oxidación |

Protección contra sobretensiones

En regiones con frecuentes fluctuaciones de energía, los fotocontroladores son siempre propensos a sufrir daños. Alta calidad sensores de fotointerruptor Integre un varistor o protección similar para absorber sobretensiones y proteger los circuitos internos. Con el tiempo, esto reduce el mantenimiento relacionado con fallos y mejora la seguridad.

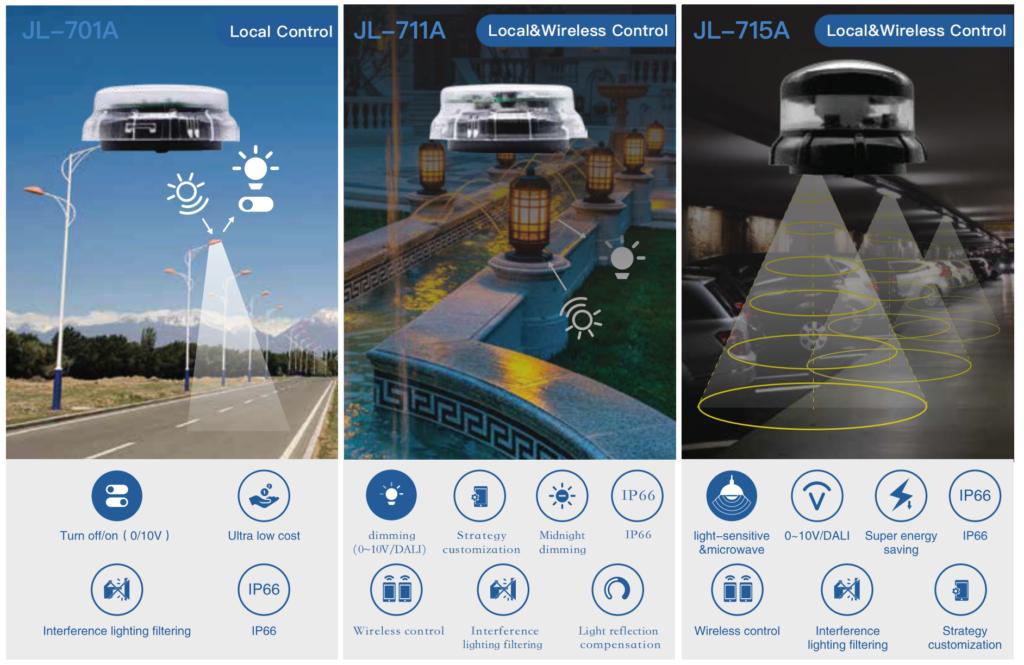

Las fotocélulas inteligentes mejoran la eficiencia de la iluminación

Moderno interruptores de luz con fotocélula Admiten protocolos de comunicación inalámbrica, como se muestra en la tabla siguiente. Estos permiten:

- Monitoreo remoto

- Control de atenuación

- Detección de fallos; y

- Integración en redes de ciudades inteligentes

Una vez implementadas, ofrecen una mayor eficiencia operativa y permiten el mantenimiento predictivo.

| Protocolo | Alcance de comunicación | Consumo de energía | Velocidad de datos |

| LoRa | Hasta 10 km | Muy bajo | Bajo |

| ZigBee | 50–100 metros | Bajo | Moderado |

| NB-IoT | 1–10 kilómetros | Moderado | Moderado |

| Wi-Fi | 100 metros | Alto | Alto |

| Malla Bluetooth | 50 metros | Muy bajo | Bajo |

Opciones OEM/ODM

Los proveedores confiables ofrecen flexibilidad OEM/ODM. Esto significa personalización del color de la carcasa, el logotipo, el embalaje y las especificaciones para su marca.

La personalización añade valor y le ayuda a diferenciarse manteniendo una calidad constante durante todo el proceso de fabricación.

¿Por qué se consideran las fotocélulas LONG-JOIN una solución fiable y de larga duración?

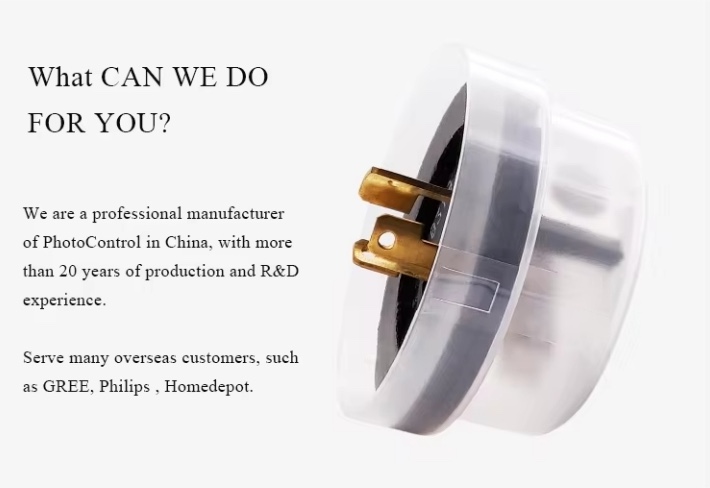

ÚNETE A LARGO PLAZO a un líder del mercado en la fabricación de fotocélulas

LONG-JOIN cuenta con más de 20 años de experiencia en el control de iluminación y la fabricación de sensores para exteriores. La empresa informa haber captado una cuota de mercado significativa en EE. UU., alrededor del 50 % (%), en ciertos segmentos de fotocélulas.

Colaboran con reconocidas marcas de iluminación a nivel mundial y cumplen con estándares de montaje como los formatos ANSI y NEMA.

Ventajas técnicas que ofrecen las fotocélulas LONG-JOIN

Los productos LONG-JOIN cumplen con las normas UL, CE e ISO, lo que garantiza componentes regulados y calidad de producción.

Incorporan características avanzadas como conmutación por cruce por cero, protección contra sobretensiones (dispositivos MOV) y compatibilidad con múltiples voltajes (por ejemplo, 120–277 V) en modelos como JL-205C. La cartera de productos abarca:

- Fotocélulas de bloqueo por giro (formato ANSI/NEMA)

- Fotocontroles cableados para luminarias modernizadas

- Receptáculos y sensores compatibles con módulos inteligentes Zhaga Book 18/series

- Fotocélulas inteligentes con capacidades IoT/inalámbricas

JOINAS DE LARGA DURACIÓN Garantizan calidad y suministro constante

La base de fabricación de LONG-JOIN incluye una instalación de 38.000 m² en Zhejiang (condado de Haiyan) con certificación ISO 9001 y líneas de producción automatizadas.

La empresa hace hincapié en los estrictos protocolos de prueba y cuenta con centros de I+D y laboratorios especializados en el control de la iluminación exterior. Además, ofrece servicios completos de personalización OEM/ODM —color de la carcasa, marca, embalaje y funciones— para fabricantes y contratistas de iluminación.

Palabras finales

Las fotocélulas fiables son vitales para una iluminación exterior segura y energéticamente eficiente. Elegir modelos certificados y de buena calidad garantiza una larga vida útil y un menor mantenimiento. Para un rendimiento fiable y un suministro constante, Chi-Swear Ofrece fotocontroladores Long-Join, en los que confían los fabricantes de iluminación mundiales por su probada durabilidad y compatibilidad con controles inteligentes.

Enlaces externos

- https://iec.ch/ip-ratings

- https://en.wikipedia.org/wiki/Varistor

- http://www.julixing.com.cn/en/new/new-58-907.html

- https://www.nema.org/docs/default-source/standards-document-library/ansi-c136-10-2017-contents-and-scope.pdf?sfvrsn=36d2efb_2

- https://www.zhagastandard.org/?view=article&id=64:book-18&catid=10

- https://www.iso.org/standard/62085.html

- https://en.wikipedia.org/wiki/LoRa

- https://en.wikipedia.org/wiki/Zigbee

- https://en.wikipedia.org/wiki/Narrowband_IoT