Describir

- Introducción

- ¿Por qué los sistemas de iluminación exterior necesitan ser resistentes? Fotocontroladores?

- ¿Cómo lo hacemos? Interruptores de fotocélula ¿Resiste la corrosión por salpicaduras de agua salada y la corrosión costera?

- Lo que mantiene nuestro Sensor de iluminación de fotocélula ¿Estable bajo calor extremo y exposición al sol?

- ¿Cómo lo hacemos? Sensores de luz ¿Sobrevivir a tormentas y sobretensiones?

- ¿Qué certificaciones demuestran nuestra fiabilidad de estándar global?

- ¿Por qué Shanghai Long-Join Electronics? Receptáculo de fotocontrol ¿Superar a la competencia en condiciones adversas?

- Palabras finales

La iluminación exterior no lo tiene fácil. Desde los vientos salados de la costa hasta el calor del desierto, fotosensores Se enfrentan a algunos de los entornos más hostiles de la Tierra. Sin embargo, estos pequeños componentes deben mantener el alumbrado público funcionando día y noche sin fallar.

¿Cómo sobreviven a tales extremos?

La respuesta reside en la ciencia de los materiales, la ingeniería de precisión y las rigurosas pruebas ambientales. En este artículo, descubriremos cómo nuestras fotocélulas mantienen su fiabilidad ante la exposición a la salinidad, el calor y las tormentas, algo que las fotocélulas convencionales no logran.

¿Por qué los sistemas de iluminación exterior necesitan ser resistentes? Fotocontroladores?

Los sistemas de iluminación exterior se enfrentan a implacables factores ambientales.

En las carreteras costeras, la salinidad del aire y las salpicaduras corroen los contactos y carcasas metálicas. La alta humedad acelera aún más la corrosión. En cambio, en el desierto, los problemas son distintos. Allí, el calor extremo y la radiación UV son los principales responsables. Las temperaturas superan con frecuencia los 50 °C, y la radiación UV agrava aún más la situación.

Esto provocó fallos en el control de la iluminación, cuyas causas comunes incluyen:

- Corrosión de las piezas metálicas y pérdida de conductividad.

- Degradación por rayos UV de cúpulas y carcasas de plástico. Esto provoca grietas y fugas.

- La entrada de agua a través de juntas dañadas o plásticos agrietados puede provocar cortocircuitos o fallos en los circuitos.

Es fundamental seleccionar materiales robustos y diseños probados. Un diseño que ha superado pruebas rigurosas demuestra su idoneidad para entornos exigentes.

En Shanghai Long-Join Electronics, aplicamos esta misma filosofía. Nuestras instalaciones y programas de pruebas garantizan que cada producto esté listo para su instalación en zonas costeras, desérticas o propensas a tormentas.

¿Cómo lo hacemos? Interruptores de fotocélula ¿Resiste la corrosión por salpicaduras de agua salada y la corrosión costera?

Los sistemas de iluminación costera se enfrentan a una constante exposición al aire salino y la alta humedad. Los iones de cloruro procedentes de la bruma marina se depositan en los terminales y contactos metálicos, creando una película conductora que acelera la corrosión electroquímica. Los plásticos tradicionales y los componentes metálicos sin tratar se deterioran rápidamente.

Nuestra ingeniería anticorrosión

- Utilizamos bases de tereftalato de polibutileno para nuestras fotocélulas. Su resistencia química a la humedad es mucho mejor que la de los plásticos estándar.

- Las cúpulas están fabricadas con policarbonato estabilizado contra los rayos UV. Este material específico se elige por su eficacia contra la corrosión.

- Todas las unidades superan la prueba de niebla salina neutra. Los parámetros de la prueba incluyen:

- Solución de NaCl 5%

- pH 6,5-7,2

- Temperatura de la cámara 35 °C

- Aplicamos recubrimientos anticorrosivos especiales en terminales y juntas. Estas características previenen la oxidación y el deterioro de los contactos eléctricos.

Rendimiento comprobado

Una vez finalizado el diseño, se prueba en instalaciones reales. Los informes muestran que estas unidades mantienen su integridad estructural y eléctrica durante mucho más tiempo que las fotocélulas estándar.

Lo que mantiene nuestro Sensor de iluminación de fotocélula ¿Estable bajo calor extremo y exposición al sol?

En zonas desérticas y tropicales, los sistemas de iluminación exterior pueden experimentar temperaturas ambiente superiores a 50 °C. En algunos lugares, la radiación UV se presenta como un factor adicional.

Según algunos estudios, Los plásticos sufren fotooxidación. Cuando se exponen a la luz solar, se vuelven quebradizos y se agrietan con el tiempo. Finalmente, es probable que penetren humedad o polvo.

Soluciones de protección térmica y UV

Implementamos diversas medidas de ingeniería para combatir estas tensiones:

- Bases de PBT resistentes al calor que mantienen su integridad estructural a altas temperaturas y resisten la deformación bajo carga sostenida. A continuación se muestra una tabla comparativa del rendimiento de los materiales.

- Cúpulas de policarbonato estabilizadas contra los rayos UV que conservan la claridad óptica y la precisión de detección de luz incluso después de una exposición prolongada al sol.

- Los sistemas electrónicos avanzados, como la tecnología de conmutación de cruce por cero, reducen la formación de arcos eléctricos en los relés y el estrés térmico durante las transiciones crepusculares/amanecer en entornos de alta temperatura.

| Tipo de material | Plástico ABS estándar | Policarbonato genérico | Mezcla de ingeniería de unión larga |

| Temperatura máxima de funcionamiento (°C) | 60 | 80 | 110 |

| Clasificación de resistencia a los rayos UV | Bajo | Moderado | Alto |

| Problemas comunes en el uso al aire libre | Deformación, decoloración | agrietamiento superficial | No se observó ninguna después de 1000 horas de prueba UV. |

| Solución de unión larga | Sustituido por PBT resistente al calor | cúpula de policarbonato estabilizada contra rayos UV | Estable en condiciones de exposición al desierto |

Probado para desiertos

Nuestros diseños se validan en zonas climáticas extremas de Oriente Medio y Asia tropical. Estas regiones se caracterizan por un calor ambiental intenso y una alta radiación solar. Los datos de campo reales demuestran nuestra eficacia. interruptores de fotocélula con sensor de luz Mantener el rendimiento sin aumentar el mantenimiento ni sufrir fallos prematuros.

¿Cómo lo hacemos? Sensores de luz ¿Sobrevivir a tormentas y sobretensiones?

Los sistemas de iluminación exterior están expuestos a descargas atmosféricas y sobretensiones eléctricas. Estos eventos generan tensiones transitorias que superan fácilmente la capacidad nominal de los circuitos de control estándar. Sin protección, interruptor de sensor de luz Los relés y los componentes electrónicos internos pueden quemarse debido a picos de tensión.

Nuestro enfoque utiliza varias medidas de protección críticas para protegernos contra estas amenazas:

- Protección contra sobretensiones integrada, como varistores o descargadores, con capacidad para eventos transitorios de hasta 10 kA/20 kV.

- Fotocélulas de anochecer a amanecer Están sellados con altos grados de protección IP para evitar la entrada de humedad, que a menudo provoca cortocircuitos.

- Los relés y componentes de conmutación de alta durabilidad se prueban más de 10.000 ciclos de encendido/apagado bajo carga.

Resiliencia comprobada

Estas características de diseño ofrecen resultados reales en ubicaciones con alta exposición a redes eléctricas inestables. En comparación con las unidades estándar que fallan prematuramente ante sobretensiones, nuestros productos requieren menos mantenimiento y menos reemplazos.

Además, aquí hay una tabla que resume el promedio de la industria en cuanto a características de protección contra sobretensiones y condiciones climáticas adversas frente a los controles de iluminación Long-Join.

| Función de protección | Protección contra sobretensiones | Clasificación IP | Resistencia en relevos |

| Promedio de la industria | 4 kA / 10 kV | IP54 | 5.000 ciclos |

| Fotocélula de unión larga | 10 kA / 20 kV | IP65 / IP66 | Más de 10.000 ciclos |

| Estándar de prueba | Norma ANSI C136.10 | IEC 60529 | IEC 60947 |

| Beneficio clave | Resiste los impactos de rayos | Bloquea la entrada de lluvia y polvo | Mayor vida útil |

¿Qué certificaciones demuestran nuestra fiabilidad de estándar global?

Nuestro sensores fotoeléctricos Ofrecemos una fiabilidad probada a través de un conjunto de certificaciones internacionales y validaciones de mercado.

Estándares clave de cumplimiento

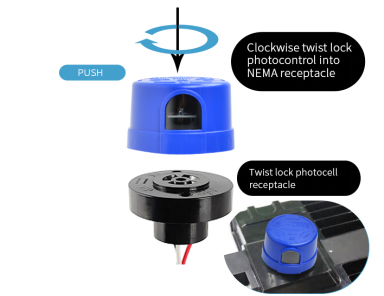

● Normas ANSI C136.10

Esto define la intercambiabilidad mecánica y eléctrica de los fotocontroles de tipo bloqueo y los receptáculos de acoplamiento en los equipos de iluminación vial.

● UL 773

Esta es la certificación norteamericana reconocida para fotocontroles de tipo bloqueo, del tipo utilizado en luminarias para exteriores.

● Libro Zhaga 18

Garantiza la compatibilidad e interoperabilidad de componentes de terceros.

● CE y RoHS

Estas certificaciones garantizan que nuestros productos cumplen con los requisitos europeos de seguridad y medio ambiente.

El cumplimiento de estas normas implica pruebas rigurosas realizadas por terceros para los criterios clave de rendimiento:

- Rango de temperatura ambiente

- Transporte de carga

- ciclos de conmutación

- Protección contra la entrada

- durabilidad mecánica y

- Compatibilidad con enchufes estándar

El cumplimiento de estas normas también facilita la logística global de instalación y adquisición para contratistas y planificadores urbanos. Grandes empresas del sector de la iluminación, como Philips y Tork, especifican la instalación de componentes que cumplen con las normas internacionales. Esto demuestra la confianza del mercado en los equipos que cumplen con las normas.

¿Por qué Shanghai Long-Join Electronics? Receptáculo de fotocontrol ¿Superar a la competencia en condiciones adversas?

Excelencia en ingeniería

Long-Join cuenta con 20 años de experiencia en control de iluminación Fabricación. La empresa opera una gran fábrica con una superficie de 38.000 m². Esta escala, junto con la automatización, garantiza la fiabilidad de cada unidad.

Ventajas para los clientes

Long-Join abastece a los principales mercados de iluminación a nivel mundial, incluyendo Norteamérica, y cuenta con una sólida capacidad exportadora. La empresa ofrece servicios de personalización OEM/ODM, lo que permite a los clientes adaptar la fotocélula a sus especificaciones.

Además, Long-Join ofrece soluciones listas para la integración y compatibles con los protocolos de ciudades inteligentes. Esto incluye:

Durabilidad por diseño

En lugar de centrarse en un solo factor de estrés ambiental, los diseños Long-Join sensores de fotocélula de luz Con una resistencia combinada frente a cualquier condición climática adversa. Gracias a que el producto está diseñado a partir de datos reales sobre el terreno, supera sistemáticamente el rendimiento de las fotocélulas convencionales.

Además, aquí hay una tabla que compara el rendimiento de los productos Long-Join con el de los productos normales. fotosensores en diversos entornos.

| Tipo de entorno | Factor de estrés | Desempeño de la competencia | Rendimiento de unión larga |

| Clima desértico | Calor + UV | Ablandamiento del material después de 6 meses | Estable después de 12 meses |

| Zonas costeras | Rociada de sal | Corrosión en los terminales | Recubrimiento anticorrosivo |

| Zonas de tormentas eléctricas | Sobretensiones | Daños frecuentes en los relés | Protección contra sobretensiones 10 kA/20 kV |

| Zonas industriales | Interferencia electromagnética | Activación falsa | Diseño con blindaje EMI |

Palabras finales

Las fotocélulas Long-Join demuestran su resistencia donde otras fallan: en calor, sal y tormentas. Su diseño ofrece una fiabilidad que resiste cualquier entorno. Para proyectos que requieren un rendimiento de iluminación exterior fiable, Chi-Swear Ofrece fotocontroladores Long-Join originales, respaldados por experiencia y una calidad constante.

Enlaces externos

- https://en.wikipedia.org/wiki/Photo-oxidation_of_polymers

- https://www.ansi.org/

- http://www.julixing.com.cn/en/new/new-58-907.html

- https://www.zhagastandard.org/?view=article&id=64:book-18&catid=10

- https://en.wikipedia.org/wiki/CE_marking

- https://en.wikipedia.org/wiki/RoHS

- https://en.wikipedia.org/wiki/Zigbee

- https://en.wikipedia.org/wiki/Narrowband_IoT

- https://en.wikipedia.org/wiki/LoRa