Nella progettazione di piscine private, il sistema di controllo della pompa viene spesso trascurato, eppure la sua affidabilità influisce direttamente sulla purezza dell'acqua, sull'efficienza energetica e sulla durata. I controller standard in plastica si corrodono rapidamente in ambienti umidi e ricchi di cloro, mentre i sensori termici economici possono malfunzionare a causa delle fluttuazioni di temperatura.

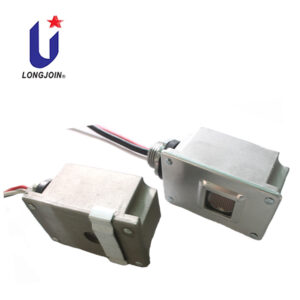

IL JL-126 Fotocontrollo termico cablato è progettato per condizioni estreme, caratterizzato da alloggiamento in lega di alluminio di grado aerospaziale, sensori in nichel-cromo di specifiche militari e elementi di fissaggio in lega di zinco anticorrosioneSì, ha un prezzo più alto rispetto ai controller generici, ma una volta compresi i vantaggi dei materiali, capirai perché vale ogni centesimo.

1. Alloggiamento in alluminio pressofuso: la massima difesa contro la corrosione della piscina

Le piscine sono ambienti brutali: fumi di cloro, spruzzi di acqua salata e continua esposizione ai raggi UV provocano crepe negli alloggiamenti in plastica economica (ABS/PP) entro 1-2 anni, mentre l'acciaio arrugginisce.

L'alloggiamento in alluminio ad alta purezza (ADC12) del JL-126 offre una protezione senza pari:

✅ Anticorrosione – Lo strato di ossido naturale dell'alluminio (Al₂O₃) resiste al cloro e al sale, durando 3–5 volte più a lungo della plastica.

✅ Dissipazione del calore superiore – L’alluminio conduce il calore 1000 volte meglio della plastica, prevenendo danni al circuito causati dal calore generato dalla pompa.

✅ Leggero ma robusto – 50% più leggero dell'acciaio inossidabile ma molto più resistente della plastica, ideale per sistemi di pompaggio soggetti a forti vibrazioni.

Risultati del test:

- Gli alloggiamenti generici in plastica si rompono dopo 3 mesi nei test in nebbia salina.

- Gli alloggiamenti in alluminio JL-126 mostrano zero corrosione dopo 5 anni.

2. Attuatore termico + compensazione della temperatura: controllo di precisione, zero falsi trigger

Le temperature delle piscine oscillano notevolmente, da massime estive di oltre 50 °C a minime invernali sotto lo zero. I sensori termici economici si espandono/contrastano in modo incoerente, causando cicli di accensione/spegnimento inutili delle pompe, con conseguente spreco di energia e accelerando l'usura.

Come risolve questo problema il JL-126:

🔥 Striscia bimetallica nichel-cromo – 60% più stabile dei sensori in rame-acciaio, garantendo la precisione da da -40°C a +70°C.

🌡️ Guarnizioni in silicone + resina epossidica – Completamente impermeabile (IP67), blocca l’umidità e le infiltrazioni di cloro.

Prestazioni reali:

- Ritardo di 30–120 secondi impedisce falsi allarmi causati da fari o fulmini.

- Compensazione automatica della temperatura mantiene soglie di commutazione costanti durante tutto l'anno.

3. Hardware anticorrosione: niente più parti arrugginite e bloccate

Niente rovina la manutenzione della piscina più velocemente di viti arrugginite e dadi bloccati che non si muove.

Ingegneria anticorrosione del JL-126:

🔩 Dadi in lega di zinco (Zamak 5) + filettature nichelate – Resistenza alla trazione ≥380 MPa, superiore ai dadi in acciaio economici (che arrugginiscono entro 2 anni).

⚙️ Giunto girevole opzionale (cuscinetto in acciaio inox + anello in PTFE) – Consente regolazioni a 360° dopo l'installazione senza danneggiare i cavi.

Confronto dei materiali:

| Componente | Soluzione JL-126 | Alternativa economica | Rischio per l'ambiente della piscina |

|---|---|---|---|

| Noci | Lega di zinco nichelata | acciaio cromato | Si blocca a causa della ruggine dopo 2 anni |

| Lente | Policarbonato resistente ai raggi UV | Acrilico standard | L'accumulo di foschia interrompe la rilevazione della luce |

| Cablaggio | Isolamento in rame stagnato + PTFE | Isolamento in PVC | Crepe dovute all'esposizione al calore/a sostanze chimiche |

4. Perché le piscine di lusso scelgono il modello JL-126?

✅ Durata decennale – Alluminio + materiali anticorrosione = manutenzione zero.

✅ Precisione impeccabile – Il sensore di livello militare evita falsi cicli di pompaggio.

✅ Installazione flessibile – Opzione giunto girevole per configurazioni di cablaggio complesse.

✅ Sicurezza certificata – Certificato UL773A, gestisce carichi pesanti (3000 VA).

In conclusione: paga una volta e rilassati per più di 10 anni

Risparmiare sulle attrezzature della piscina porta a frequenti riparazioni e sostituzioni anticipate. JL-126 Fotocontrollo termico—con il suo metalli di qualità aeronautica, sensori di precisione e design resistente al cloro—è l'investimento ideale per un funzionamento senza problemi.

"Costoso? Sì. Ne vale la pena? Assolutamente."

📞 Aggiorna oggi stesso il sistema di controllo della tua piscina:contattaci per i dettagli!