Schema

- Introduzione

- Come fare Fotosensori Aiutare i sistemi di illuminazione esterna?

- Che cosa è un MOV e perché è fondamentale in Controllo dell'illuminazione Progetto?

- In che modo un MOV protegge effettivamente un driver LED?

- Perché alcuni clienti scelgono MOV con rating inferiore come 471K?

- Cosa succede realmente se si sostituisce 821K con 471K in un sistema da 277 V?

- Cosa dicono gli standard UL sulla selezione dei MOV?

- In che modo Long-Join garantisce l'affidabilità del MOV nel suo Interruttori con sensore di luce?

- Perché un singolo guasto del MOV può mettere a repentaglio l'intera rete di illuminazione?

- Come possono gli OEM e i progettisti scegliere il MOV giusto?

- Parametri chiave UL773 e IEC 61000-4-5 per Interruttore fotocellula luce MOV

- Parole finali

Sensori di luce fotocellula per esterni sono spesso riconosciuti per il loro ruolo nell'accensione e nello spegnimento delle luci. Ma all'interno di ogni sensore c'è un piccolo componente che difende silenziosamente il tuo sistema: il Varistore in ossido metallico (MOV).

Questo dispositivo protegge il driver LED da sovratensioni improvvise, fulmini o tensioni di rete instabili. Tuttavia, non tutti i MOV sono uguali. Scegliere una potenza nominale errata può danneggiare silenziosamente il driver e ridurre la durata del sistema di illuminazione.

Questo articolo spiega perché l'abbassamento della tensione nominale dei MOV è un rischio nascosto in ambienti esterni sensore di luce progetto.

Immagine per gentile concessione: Marchi di acuità

Come fare Fotosensori Aiutare i sistemi di illuminazione esterna?

Fotocontrollori Regolano il livello di luce in base alla luce naturale. Questi dispositivi possono resistere efficacemente a condizioni difficili grazie alle loro caratteristiche, tra cui:

- Alloggiamenti con grado di protezione IP

- Lenti stabili ai raggi UV

- Intervallo di temperatura da -40 °C a +65 °C

Ma molte persone pensano solo al sensore di luce e il relè di commutazione. Ciò che spesso trascurano sono i componenti di protezione interni. Questi includono elementi di protezione da sovratensione, come i MOV, che difendono il driver LED da picchi di tensione, sovratensioni di commutazione della rete e transitori.

Senza queste protezioni, anche il bene prese fotocontrollate guasti prematuri. I contatti dei relè si saldano, i semiconduttori si surriscaldano e i driver si danneggiano.

Che cosa è un MOV e perché è fondamentale in Controllo dell'illuminazione Progetto?

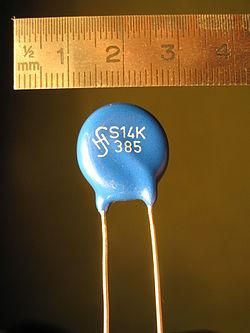

Un varistore a ossido metallico (MOV) è un resistore non lineare costituito da grani di ossido di zinco sinterizzati e altri ossidi. A tensioni normali, ha una resistenza molto elevata e consente solo una minima corrente di dispersione.

In caso di sovratensione, la tensione supera la soglia (varistore/tensione di bloccaggio).Evento di sovratensione: la tensione supera la soglia (varistore/tensione di bloccaggio).

Perché i MOV sono consumabili e come si degradano

Ogni volta che un MOV gestisce una sovratensione transitoria, si riscalda internamente, causando micro-danni alla sua struttura ceramica. Sovratensioni ripetute riducono leggermente la sua soglia di clamping e aumentano la corrente di dispersione a tensioni normali. Col tempo, si "deteriora".

Potrebbe degradarsi al punto che piccole fluttuazioni di tensione (che dovrebbero essere innocue) iniziano a innescarlo. Ciò causa maggiore usura, maggiori perdite e maggiori rischi. Ecco una tabella con le tensioni nominali dei MOV in base alle applicazioni tipiche.

| Modello MOV | MCOV (V) | Utilizzo tipico della rete | Note |

| 471 mila | 300 V | Solo 120–220 V | Non sicuro a 277V |

| 511 mila | 320V | 220–240 V | Scelta equilibrata |

| 821 mila | 510V | Sistemi 277V | Standard per la conformità UL |

In che modo un MOV protegge effettivamente un driver LED?

Immagine per gentile concessione: Wikipedia

A tensione di rete normale, il MOV rimane non conduttivo. Assorbe solo corrente di dispersione in microampere, senza produrre alcun effetto percepibile. Senza sovratensioni, rimane in silenzio, lasciando che tutto il resto funzioni.

In caso di sovratensione o transitorio (fulmini, commutazione di rete, guasti), la tensione supera la soglia di clamping del MOV (ad esempio, ~800 V o superiore in alcuni casi). La resistenza del MOV diminuisce rapidamente. La corrente di sovratensione viene deviata verso terra o verso il neutro, evitando al driver LED sovratensioni.

Rischi senza protezione MOV

- I semiconduttori interni del driver LED (raddrizzatori a ponte, condensatori) rilevano tensioni superiori ai loro valori nominali, causando guasti dielettrici o bruciature dei componenti.

- Lo stress termico si accumula a causa di ripetute piccole sovratensioni, anche se nessuna di queste è immediatamente catastrofica. Ciò porta a una riduzione della durata utile o a guasti improvvisi.

- Nel caso peggiore, il driver si guasta, l'apparecchio si guasta completamente, e potrebbe addirittura verificarsi un cortocircuito o un incendio se il MOV si guasta in modo catastrofico.

Perché alcuni clienti scelgono MOV con rating inferiore come 471K?

Alcuni ritengono che una tensione di clamping inferiore offra una protezione più rapida. Se il MOV inizia a condurre a una soglia inferiore, presumono che intercetterà le sovratensioni prima. Lo considerano una maggiore sicurezza. Inoltre, i componenti con una tensione di clamping inferiore potrebbero costare meno o apparire più "sensibili".

Conseguenze reali dell'utilizzo di 471K in un sistema da 277V

- In molte reti, la tensione oscilla di ±5-10%. Un MOV con MCOV (tensione di esercizio continua massima) troppo bassa o una soglia di clamping troppo bassa, come 471K (~305V), si attiverà durante le normali variazioni. Ciò causa attivazioni frequenti. Ogni attivazione degrada il MOV, che si usura più rapidamente del previsto.

- I MOV con potenza nominale inferiore (non certificati) potrebbero violare gli standard (UL, IEC) per sistemi funzionanti a 277 V o superiori. Ciò comporta non conformità, rischi assicurativi e responsabilità civile.

Ecco una tabella che illustra i segnali più comuni di degradazione dei MOV per i tecnici sul campo.

| Sintomo | Causa probabile | Azione richiesta |

| Segni di bruciatura su MOV | Colpi ripetuti | Sostituisci MOV |

| Aumento della corrente di dispersione | Invecchiamento del MOV | Sostituisci driver o MOV |

| Errore silenzioso (aperto) | Fine vita del MOV | Controllare lo stato del conducente |

| guasto da cortocircuito | Grave esaurimento da sovratensione | Necessaria sostituzione immediata |

Cosa succede realmente se si sostituisce 821K con 471K in un sistema da 277 V?

Questo potrebbe sembrare protettivo, ma non lo è. In realtà, il 471K percepirà le normali oscillazioni della rete come sovratensione. Questo fa sì che il MOV conduca frequentemente durante il funzionamento quotidiano.

La conduzione frequente riscalda il MOV e causa danni microscopici. Ogni evento riduce la sua capacità di gestione dell'energia e ne modifica il comportamento di serraggio. Ben presto, la perdita del MOV aumenta e il suo serraggio nominale diminuisce.

A quel punto, il MOV si guasta, si apre, si cortocircuita o entra in runaway termico. Quando il MOV si guasta, il driver LED rimane senza protezione. Questo lascia condensatori, raddrizzatori e circuiti integrati di controllo esposti alla successiva sovratensione effettiva. Questo si traduce ulteriormente in guasti del driver, interruzioni dell'apparecchio e maggiori costi di garanzia e di intervento sul campo.

Principali effetti pratici in un'installazione da 277 V

- Frequenti falsi scatti con variazioni di alimentazione di ±5–10%.

- Degrado accelerato della valutazione dell'energia di serraggio del MOV.

- Maggiore probabilità di guasto catastrofico in caso di sovratensione ad alta energia.

Cosa dicono gli standard UL sulla selezione dei MOV?

UL guida e Norme SPD richiedono la selezione del valore MCOV di un SPD in base alla tensione di sistema. Il MCOV è la massima corrente alternata continua che il dispositivo può vedere senza condurre.

UL-773 (fotosensore standard) e le linee guida SPD di tipo 3 richiedono componenti e progetti appropriati per la tensione di alimentazione nominale dell'unità di controllo. Fotocontrolli con tensione nominale di 277 V CA, è necessario utilizzare una protezione il cui MCOV impedisca la conduzione alla normale tensione di linea.

Perché 471K non funziona per i sistemi a 277 V

Il valore MCOV nominale di un dispositivo 471K (intervallo ~300 V o inferiore) è troppo vicino al picco di linea a 277 V CA. Questa vicinanza implica che le normali variazioni di linea possono spingere il MOV verso la conduzione o verso perdite elevate, violando l'intento della selezione del MCOV.

L'utilizzo di un dispositivo di questo tipo comporta il rischio di non conformità alle specifiche UL/IEC e può invalidare la garanzia o l'accettazione normativa. Ecco una tabella di riferimento rapido.

| Modello MOV | MCOV tipico (circa) | Conformità UL/IEC per sistemi a 277 V | Sicuro per 277 V? |

| 821 mila | ~510 V | Sì (adatti progetti con MCOV elevato). | SÌ |

| 511 mila | ~320 V | Sì (soddisfa le linee guida MCOV ≥ ~320V). | SÌ |

| 471 mila | ~300 V | Spesso no (MCOV troppo basso per 277 V) | NO |

In che modo Long-Join garantisce l'affidabilità del MOV nel suo Interruttori con sensore di luce?

Long-Join ha oltre 20 anni di esperienza come produttore di controlli dell'illuminazione esternaLa serie JL-205 (inclusa la JL-205C) è dotata di protezione da sovratensioni (MOV) integrata in tutte le unità.

Utilizzano solo modelli certificati UL per i loro condizionatori standard controlli di illuminazione (120-277 VAC), assicurando che il MCOV dei MOV sia adatto a tali tensioni.

È possibile personalizzare il MOV. Ad esempio, le opzioni di "livello di protezione da sovratensioni" del JL-205C includono:

- 12 = 110J/3500A

- 15 = 235J/5000A

- 23 = 460 J/10.000 A

Questi valori di joule più elevati significano che il MOV può assorbire più energia senza degradarsi prematuramente. Long-Join offre modelli come JL-205C, JL-207C, JL-243C che combinano:

- ANSI/Conformità UL773 per plug-in o twist-lock fotocontrolli.

- MOV integrati dimensionati per le tipiche sovratensioni della rete esterna.

Garantiscono inoltre la durabilità ambientale

- I gusci sono resistenti ai raggi UV

- classificazioni IP fino a IP65/IP67

- Temperatura di esercizio da -40 °C a +70 °C

Perché un singolo guasto del MOV può mettere a repentaglio l'intera rete di illuminazione?

Un singolo MOV guasto spesso interrompe la protezione del driver LED. Senza tale protezione, sovratensioni o anomalie di rete raggiungono direttamente il driver. I driver contengono componenti sensibili: condensatori, diodi e circuiti integrati. Questi sono vulnerabili.

In una rete di illuminazione stradale intelligente o in un'installazione industriale, il guasto di un apparecchio ha conseguenze a cascata:

- Guasto del driver → la spia si spegne → la rete segnala un guasto → è necessaria la manutenzione.

- Se molti MOV si guastano, molti conducenti perdono la protezione → guasti diffusi.

Gli studi dimostrano che i MOV sottoposti a stress da ripetute sovratensioni subiscono danni termici, maggiori perdite e alla fine si guastano per cortocircuito o circuito aperto. Se la protezione si guasta silenziosamente, non c'è alcun preavviso finché il driver LED non viene distrutto. In tal caso, i costi sono la sostituzione dell'apparecchio, interruzioni di corrente e rischi per la sicurezza.

Come possono gli OEM e i progettisti scegliere il MOV giusto?

- Controlla sempre prima la tensione massima di tenuta del tuo driver. Il serraggio del MOV deve essere al di sotto di quella tollerabile dal tuo driver LED.

- Evitate valori MOV troppo bassi: si attivano con le normali oscillazioni della linea e si degradano rapidamente.

- Evitare valori troppo alti, poiché il MOV potrebbe non bloccarsi rapidamente per arrestare un'ondata di tensione.

- Assicurarsi che i MOV siano conformi agli standard come UL e CEITali standard definiscono la tensione di serraggio richiesta, la corrente di sovratensione (IPP) e le forme d'onda impulsive.

- Considerare anche la durata di vita in condizioni di esposizione a sovratensioni previste. Utilizzare schede tecniche o rapporti di prova che indichino la durata di vita a impulso, la corrente di dispersione dopo l'invecchiamento e la classificazione energetica.

Parametri chiave UL773 e IEC 61000-4-5 per Interruttore fotocellula luce MOV

| Standard | Requisito | Impatto della selezione MOV |

| UL773 | MCOV ≥ 320V per 277V | Elimina 471K |

| UL773 | Test di resistenza alle sovratensioni | Garantisce una lunga durata di servizio |

| Norma CEI 61000-4-5 | Forma d'onda 8/20µs | Il MOV deve corrispondere alla classificazione energetica di sovratensione |

| Norma CEI 61000-4-5 | Test di impulso ripetuto | Convalida la durabilità del MOV |

Parole finali

I MOV sono piccoli ma essenziali nella progettazione delle fotocellule. Una scelta sbagliata può ridurre la vita utile di un driver e mettere a rischio intere reti. Una selezione accurata garantisce prestazioni durature. Per soluzioni affidabili, Chi-Swear offre fotocontrollori intelligenti LongJoin con MOV conformi agli standard UL. La loro competenza e i loro design collaudati li rendono un partner affidabile.