Schema

- Introduzione

- What Is Zero‑Cross Control Technology and Why Is It Important?

- How Does Zero‑Cross Control Work Inside a Photocontroller?

- What Does a Typical Zero‑Cross Circuit Look Like?

- Which Methods Are Commonly Used for Zero‑Cross Detection?

- What Engineering Advantages Does Zero‑Cross Control Bring to Prese fotocontrollate?

- Why Should You Choose the JL‑207 Interruttore sensore luce for Your Project?

- Parole finali

Tired of fotosensori burning out too fast or causing electrical noise? The problem often lies in how and when circuits are switched. That’s where Zero-Cross Control Technology comes in.

It switches power exactly at the safest moment—when the current hits zero. No arcs. No surges. Just clean, quiet switching. In this article, we’ll explore how this smart technology works and why it’s a game-changer for street lighting and interruttori fotocellula.

What Is Zero‑Cross Control Technology and Why Is It Important?

Zero‑Cross Control Technology switches AC circuits exactly when voltage crosses zero. At this point, the voltage is neither positive nor negative. This prevents current surges and arcing that occur when switching at other points.

The AC waveform crosses zero twice each cycle. At zero, voltage and current are minimal. This makes it the safest moment to open or close a circuit. Switching here avoids arcs and reduces stress on electrical components.

Zero‑Cross vs. Peak Switching

Peak switching happens mid‑cycle when voltage is high.

- Results in current surges (“inrush”)

- Creates harmful electromagnetic interference (EMI)

- Can damage relay contacts or TRIACs

Zero‑cross switching avoids all these pitfalls, delivering clean and reliable circuit operation

Vantaggi principali

- It limits inrush current during power-up, especially with LED or capacitive loads.

- It also reduces EMI, keeping systems interference-free.

- Finally, it extends the life of all key parts by lowering electrical stress.

How Does Zero‑Cross Control Work Inside a Photocontroller?

Moderno interruttori con sensore di luce use a tight hardware + software loop to switch only at the safest moment—zero current.

Zero‑Cross Detection Circuit

A built‑in zero‑cross detector monitors the AC waveform. At each zero voltage point, it instantly signals the MCU. MCUs with on‑chip ZCD peripherals (like PIC/AVR) can detect this with minimal external parts—just a resistor to the mains line.

Microcontroller (MCU)

Upon receiving the zero‑cross signal, the MCU quickly decides whether to allow switching. It can introduce a slight delay (phase‑angle control), or simply trigger the output immediately for full-cycle switching.

Triac or Relay Switch

The MCU turns on a TRIAC or relay at the next zero‑cross. TRIACs, especially opto-triac types with zero-cross feature inside the package, latch on cleanly at zero voltage.

Real-Time Monitoring & Execution

- AC waveform keeps rising and falling twice each cycle.

- Detector flags every zero-crossing edge (positive or negative).

- MCU handles interrupts and triggers switching logic within microseconds.

- TRIAC or relay closes circuit only at zero —no arcs, no EMI, no stress.

Thanks to this coordination, switching happens exactly at zero voltage. Inrush currents are avoided. No contact arcing occurs. Results are safer and longer-lasting photocell operation.

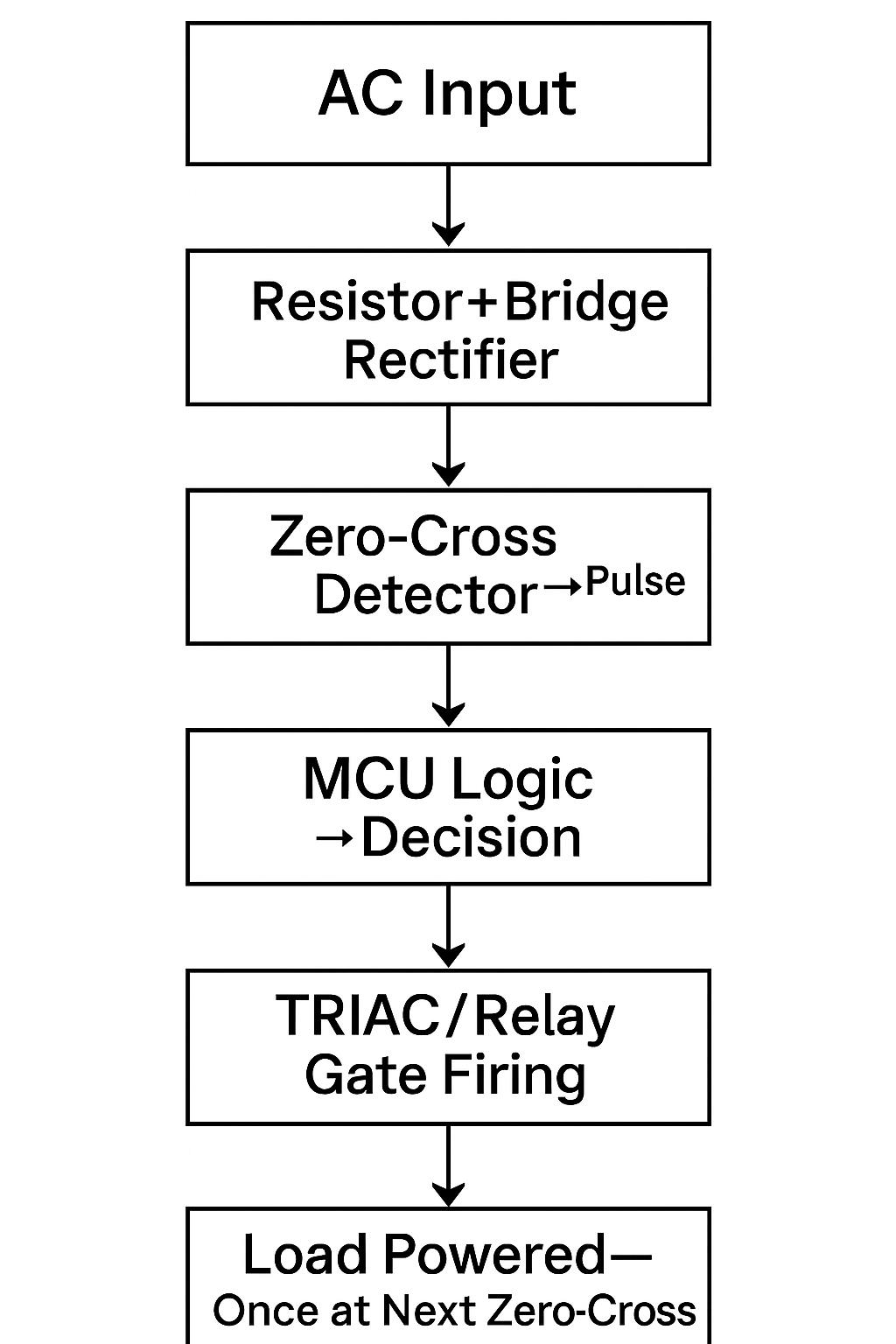

What Does a Typical Zero‑Cross Circuit Look Like?

Below is a step‑by‑step walkthrough of a simplified zero‑cross AC switching circuit found in smart prese fotocontrollate.

1. Input AC & Rectification

AC mains voltage enters the controller. A resistor and bridge rectifier convert it into a waveform suitable for detection. This prepares the signal for safe sensing.

2. Zero‑Cross Pulse Generation

The rectified waveform feeds an optocoupler or comparator circuit. At each zero-voltage crossing, it emits a tidy pulse. For example, Toshiba’s Zero‑Cross Phototriac stops triggering until voltage drops below ~±15 V.

3. MCU Response Logic

The MCU receives the zero‑cross pulse via interrupt. It then decides: turn ON or stay OFF. For phase control, it adds firing delays. For full-cycle switching, it triggers immediately. PIC MCUs with built-in ZCD peripherals simplify this task and reduce external parts.

4. TRIAC or Relay Execution

The MCU fires a signal to the TRIAC or relay gate at the next zero-cross. Opto-triac modules latch cleanly only near zero crossings, offering built-in isolation. Relays can also be triggered at zero but require precise timing to avoid delay.

Here is a simple circuit visualization.

How This Achieves Zero‑Arc Switching

- Circuit only switches when voltage is nearly zero.

- Inrush currents stay minimal.

- No arcs—no sparks—when switching.

- EMI and stress on components are drastically reduced.

Which Methods Are Commonly Used for Zero‑Cross Detection?

Moderno sensori fotocellule crepuscolari rely on one of three core zero‑cross detection techniques. Each balances precision, safety, and cost differently.

Optocoupler Isolation Method

An optocoupler isolates AC mains from the control logic via light. A resistor biases the LED; the phototransistor output triggers a pulse at each zero-crossing. This method offers robust galvanic isolation and simplifies safety compliance. It’s widely used in industrial-grade lighting controls.

The drawback: modest power loss in the LED and extra parts cost.

Op‑Amp / Comparator Circuit

A comparator or op‑amp compares the AC waveform against a zero-volt reference. When the waveform crosses zero, the output flips state, forming a square pulse.

Hysteresis is often added to filter noise and prevent false detection. Comparators are fast and affordable, but provide no isolation and require careful input protection and filtering.

Direct MCU Sensing (with Protection)

Some microcontrollers include built-in zero‑cross detection peripherals. These can sense mains voltage via a resistor (and sometimes capacitor) and generate interrupts directly.

This approach reduces BOM cost and component count. But it demands strict input protection to guard the MCU substrate from voltage injection. It also lacks isolation unless external components are added.

| Method | Isolation | Precisione | Component Cost |

| Optocoupler | Eccellente | Moderare | Medio |

| Op‑Amp/Comparator | Nessuno | Alto | Basso |

| Direct MCU Sensing | Alone | Moderate‑High | Very Low (few parts) |

Industry-Preferred Choice

Most commercial interruttori con sensore di luce esterna prioritize safety and regulatory compliance. They typically use opto‑isolator-based detection combined with simple resistors, diodes, and filtering.

This approach balances precision, isolation, and cost. It’s reliable across varied environments—making it industry standard for robust zero‑arc switching operation.

What Engineering Advantages Does Zero‑Cross Control Bring to Prese fotocontrollate?

- Prevents arcing, reducing wear on relay contacts.

- Minimizes inrush current to safeguard LED drivers.

- Reduces electromagnetic interference during switching.

- Enhances operational safety in sensitive electrical networks.

- Extends the service life of relays and switching components.

- Ensures smoother power-up in inductive and capacitive loads.

- Decreases thermal stress on power modules and PCBs.

- Enables high-frequency switching without performance loss.

- Lowers maintenance costs due to fewer component failures.

- Increases overall reliability of outdoor lighting systems.

Why Should You Choose the JL‑207 Interruttore sensore luce for Your Project?

IL JL‑207 series from Long‑Join Electronics is designed to deliver smart, reliable outdoor lighting control—and it stands out for good reasons.

MCU‑Driven Smart Logic

Each unit features an onboard microcontroller. It handles ambient light detection, zero‑cross timing, and configurable delays. This ensures precision switching and avoids false triggers from fleeting light changes.

Built‑In Zero‑Cross Circuit

Zero‑cross protection is integrated as an optional feature. That ensures switching occurs exactly at zero voltage, eliminating arcs and extending relay life.

Durable Heavy‑Duty Relay

JL‑207C models offer standard relays rated for over 10,000 cycles. High‑power (HP) versions boost this to 20 A or more, and metal‑armor shells push lifespan to 50,000+ cycles. Built‑in surge protection (MOV or R/C) guards against spikes.

ANSI/UL Standards Compliance

- Designed to ANSI C136.10 twist‑lock socket standards

- UL 773 listed for use in the U.S. and Canada

- CE E Direttiva RoHS certified

- Options include Commissione federale delle comunicazioni Class A/B EMI suppression

Parole finali

Zero-cross control is not just a feature—it’s a smart solution for longer-lasting, safer lighting. It protects your system and improves performance with every switch. For trusted quality, Chi-Swear offers Long‑Join smart photocells built to meet these advanced standards.

Link esterni

- https://en.wikipedia.org/wiki/Zero-crossing_control

- https://www.sciencedirect.com/topics/engineering/electromagnetic-interference

- https://en.wikipedia.org/wiki/Microcontroller

- https://www.nema.org/standards/technical/ansi-c136-series-standards-for-roadway-and-area-lighting-equipment

- http://www.julixing.com.cn/en/new/new-58-907.html

- https://single-market-economy.ec.europa.eu/single-market/goods/ce-marking_en

- https://en.wikipedia.org/wiki/RoHS

- https://www.fcc.gov/