Outline

- Introduction

- Why Is Salt Spray Resistance Critical in Outdoor Lighting Systems?

- What Exactly Is NSS (Neutral Salt Spray) Testing?

- Who Needs Salt Spray‑Resistant Lighting Components?

- How Does Long‑Join Ensure Superior Salt Spray Resistance?

- What Are the Long-Term Benefits of Choosing NSS-Tested Long-Join Photocell Sensors?

- The Bottom Line

Outdoor lighting doesn’t just need to work — it needs to survive. In coastal cities, humid climates, or polluted industrial zones, corrosion is the enemy. Salt in the air can eat away at enclosures, terminals, and connectors. Over time, that means flickering lights, failed lighting controls, and costly maintenance.

That’s why salt spray resistance isn’t optional — it’s essential. At Long-Join, we design and test our products to stand up to these harsh conditions so your lighting lasts longer and works better.

Why Is Salt Spray Resistance Critical in Outdoor Lighting Systems?

Salt spray and pollutant-led corrosion are genuine issues in coastal and humid areas. Chloride ions settle on metal and pull in moisture. This forms a conductive layer that sparks electrochemical corrosion. It weakens connectors, raises resistance, and can cause failure within months.

Here is a table explaining common failures in lighting components due to corrosion.

| Component Affected | Typical Corrosion Issue | Resulting Failure |

| Terminal Contacts | Oxidation and pitting | Signal loss or intermittent power |

| Plastic Enclosures | UV and salt fog degradation | Cracking or warping |

| Metal Screws and Clips | Rust formation | Loose fitting or structural failure |

| PCB Traces | Corrosion bridging | Short circuits |

Environmental Stress Zones

Coastal areas

Sea winds carry sodium chloride, aka the salt. This even from miles away corrodes aluminum and steel.

High-humidity regions

Moisture collects on enclosures. With polluted air, corrosion speeds up.

Industrial and polluted zones

Sulfur dioxide, acid rain, and fertilizers coat components. These speed up material breakdown.

Material Degradation and Failure Modes

Rust forms on connectors. Terminals loosen. Resistance increases, which raises heat and fire risk. Some plastics absorb moisture. They swell and lose strength. Seals degrade with time.

These effects can lead to:

- Failed connections

- Short circuits

- Pitting and discoloration

- Cracking and seal failure

Corrosion-resistant materials and coatings prevent these issues. For example:

- Anodized or PVDF-coated aluminum lasts over 3,000 hours in salt fog tests.

- Zinc-nickel or electroplated layers survive hundreds of hours in NSS testing.

These solutions cut rust, reduce failures, and extend service life.

What Exactly Is NSS (Neutral Salt Spray) Testing?

NSS testing is an accelerated corrosion test. It recreates coastal or marine air in a controlled lab environment. This is mostly employed in the lighting and electrical industries.

Manufacturers rely on it to check corrosion resistance. The test confirms that enclosures, connectors, and coatings can survive in high-salinity environments.

Image Courtesy: Wikipedia

Standard Test Parameters

The testing conditions are tightly controlled:

- Salt solution including 5% NaCl by weight in demineralized water.

- pH value around neutral range, typically 6.5–7.2

- Chamber temperature of 35 °C ±1 °C

- Salt fog fallout is about 1.0–2.0 ml per 80 cm² per hour

- Test durations are commonly 24–96 hours. This can extend up to 240 hours or more for marine-grade components

How NSS Simulates Real‑World Conditions

- It forces concentrated salt fog onto test samples, mimicking relentless sea breeze.

- Moisture condenses constantly on parts, replicating dew or humidity exposure.

- The elevated temperature speeds up any chemical corrosion reactions.

- Extended exposure times (up to hundreds of hours) simulate multi-year natural wear in days.

Who Needs Salt Spray‑Resistant Lighting Components?

Coastal Smart Cities

Cities along the sea face constant salt-air exposure. Municipal lighting systems in Florida, Chile, Dubai, and similar regions demand corrosion‑resistant components. Coastal tenders often require fixtures certified to salt spray testing. Without it, lights develop rust, discolor, and fail.

Government & Municipal Bids

Public tenders often require at least 96-hour NSS compliance. This is a critical threshold for photosensors to qualify for infrastructure contracts.

Airports & Military Installations

Airports, military bases, and naval facilities demand maximum reliability. These sites can’t afford corrosion-related failures. Thus, to ensure safety and uptime, all components must resist prolonged salt spray exposure.

Global Lighting OEMs and Brands

Top manufacturers like Philips, Cree, and Southwire demand corrosion-tested accessories. Every part must meet or exceed NSS benchmarks. This guarantees performance and quality in OEM lighting systems.

Industrial & Polluted Zones

Acid rain and sulfur-rich air boost corrosion in polluted zones. Lighting in these areas faces dual threats—salt and chemical exposure. NSS testing validates that materials can handle both stresses.

How Does Long‑Join Ensure Superior Salt Spray Resistance?

Materials Engineered for Endurance

Long‑Join uses UV‑stabilized PC, PP, and PBT plastics in its enclosures. These resist UV degradation and moisture uptake, even in marine climates. Its brass terminals are plated with nickel or tin. This plating prevents oxidation at contact points and extends service life.

Here is a table outlining LongJoin material and coating choices vs corrosion protection impact.

| Material/Coating | Corrosion Protection Role | Used On |

| UV-Stabilized Polycarbonate | Prevents brittleness and yellowing | Photocontrol domes |

| Tin-Plated Brass | Inhibits rust and contact oxidation | Socket terminals |

| PBT with Glass Fillers | Resists chemical wear and moisture | Zhaga receptacles |

| Silicone Rubber Gaskets | Seals out salt-laden air and water | Enclosure lids |

Robust Testing Capabilities

Long‑Join operates its own in‑house salt spray chamber. It can test components under Neutral Salt Spray (NSS) conditions for up to 240 hours. This goes well beyond standard thresholds. Customers also have the option to request third‑party validation of results from labs like SGS or DEKRA.

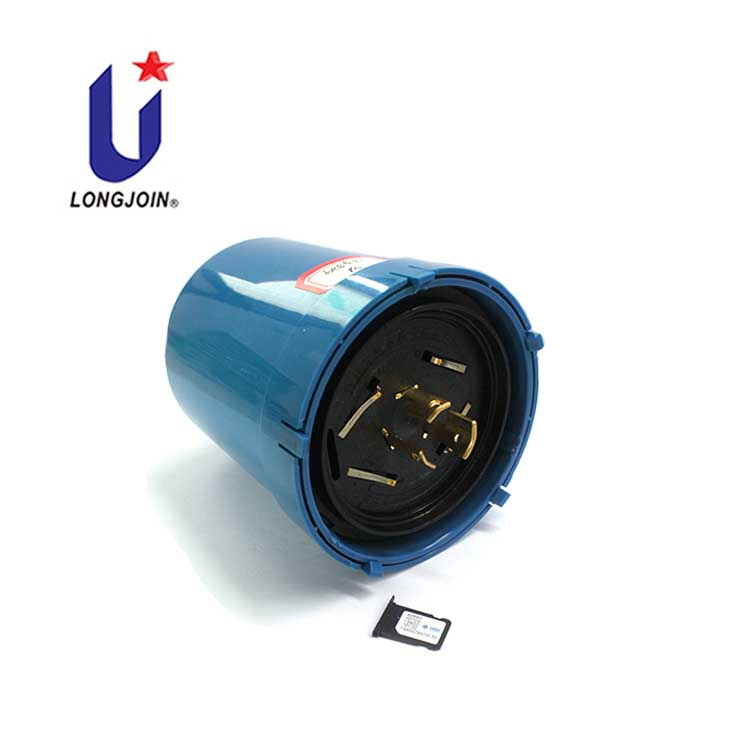

Comprehensive Component Coverage

Every product in their range undergoes NSS testing:

- Photocontrol receptacles (day/night light sensors)

- NEMA sockets and Zhaga receptacles

- Adapter accessories tied to outdoor lighting controls

This ensures all connection points are protected from corrosion.

Quality Assurance Integration

Salt spray resistance isn’t an afterthought. It’s built into Long‑Join’s entire QA process. Each production batch is tested against NSS standards. Reports are kept on file. Failures trigger immediate process reviews so that only NSS‑compliant units are shipped.

What Are the Long-Term Benefits of Choosing NSS-Tested Long-Join Photocell Sensors?

Extended Product Lifespan

Long-Join’s NSS-tested street light controllers, sockets, and receptacles resist salt, humidity, and airborne pollutants. In coastal or industrial zones, they last much longer. These parts don’t crack, corrode, or wear out early.

Lower Maintenance Costs

Non-tested products often fail due to rusted contacts or damaged shells. NSS-tested units avoid these problems. This ultimately means lower maintenance bills for cities and utilities. Here is a simple maintenance cost comparison of Non-NSS vs NSS.

| Scenario | Avg. Replacement Frequency | Estimated Labor Visits | Total Cost (USD) |

| Non-NSS Compliant Product | Every 18–24 months | 3–4 | $150–$200 |

| NSS-Tested Long-Join Product | Every 5+ years | 1 | $50–$70 |

Standards Compliance

Many global and city tenders require at least 96-hour NSS resistance. Long-Join offers up to 240 hours of protection. All test results are certified by labs or verified in-house, making the products ready for public use.

System Reliability in Harsh Conditions

Smart lighting depends on smooth data flow and steady power. Corrosion can block signals or kill power unexpectedly. NSS-tested components prevent these issues and keep systems stable in tough environments like monsoons or sea mist.

Confidence for Planners and OEMs

City planners and OEMs want more than promises—they want proof. Long-Join backs its products with salt spray test reports and success in harsh coastal zones. That track record builds trust for critical deployments where failure isn’t an option.

The Bottom Line

Salt spray resistance isn’t optional—it’s vital for lighting systems in tough environments. Long-Join smart photocells are built to endure and perform where others fail. For trusted, corrosion-tested solutions, Chi‑Swear is your go-to source for Long‑Join quality.

External Links

- https://www.researchgate.net/publication/290042889_Effect_of_sea_salt_and_relative_humidity_on_corrosion_rate_of_carbon_steel_in_humidity_test

- https://en.wikipedia.org/wiki/Salt_spray_test

- https://www.assuredtesting.com/iso-9227-salt-spray-testing

- https://www.sgs.com/en

- https://www.dekra.com/en/about-dekra/

- https://www.nema.org/

- https://www.zhagastandard.org/index.php?option=com_content&view=article&id=340:zhaga-enables-iot-upgradeable-outdoor-led-lighting-fixtures&catid=22