Outline

- Introduction

- Why Do Outdoor Lighting Systems Need Tough Photocontrollers?

- How Do Our Photocell Switches Resist Salt Spray and Coastal Corrosion?

- What Keeps Our Photocell Lighting Sensor Stable Under Extreme Heat and Sun Exposure?

- How Do Our Light Sensors Survive Storms and Power Surges?

- What Certifications Prove Our Global-Standard Reliability?

- Why Do Shanghai Long‑Join Electronics Photocontrol Receptacle Outperform Competitors in Harsh Conditions?

- Final Words

Outdoor lighting doesn’t get an easy life. From salty coastal winds to desert heat, photosensors face some of the harshest environments on earth. Yet, these small components must keep streetlights running day and night without fail.

How do they survive such extremes?

The answer lies in material science, precision engineering, and rigorous environmental testing. In this article, we’ll uncover how our photocells stay reliable through salt spray, heat, and storms—when ordinary ones simply can’t.

Why Do Outdoor Lighting Systems Need Tough Photocontrollers?

Outdoor lighting systems face relentless environmental stressors.

Along coastal roads, salt air and spray attack metal contacts and housings. High humidity further accelerates corrosion. Conversely, in the desert, the challenges are different. Here, extreme heat and UV became the culprit. Temperatures regularly exceed 50 °C, and UV radiation comes as a cherry on top.

This led to lighting control failure, with common causes including

- Corrosion of metal parts and loss of conductivity.

- UV-degradation of plastic domes and housings. This leads to cracks and leakage paths.

- Water ingress through compromised seals or cracked plastics. This can cause shorts or malfunctioning circuits.

Selecting robust materials and proven designs is critical. A design that has passed rigorous tests demonstrates suitability for harsh deployments.

At Shanghai Long‑Join Electronics, we apply this exact philosophy. Our facility and test programmes ensure each product is ready for coastal, desert, or storm-prone installation.

How Do Our Photocell Switches Resist Salt Spray and Coastal Corrosion?

Seaside lighting systems face a constant barrage of salt air and high humidity. Chloride ions from sea spray settle on terminals and metal contacts. This creates a conductive film that accelerates electrochemical corrosion. Traditional plastics and untreated metal components fail quickly.

Our Anti-Corrosion Engineering

- We employ polybutylene terephthalate bases for our photocells. Their chemical resistance against moisture is much better than standard plastics.

- The domes are made from UV-stabilised polycarbonate. This specific material is chosen for its effectiveness against corrosion.

- All units pass the Neutral Salt Spray test. The test’s parameters include:

- 5% NaCl solution

- pH 6.5-7.2

- Chamber temperature 35 °C

- We apply special anti-corrosion coatings on terminals and gaskets. These features prevent oxidation and deterioration of electrical contacts.

Proven Performance

Once the design is finalized, it is then tested in real-world installations. Reports show these units maintain structural and electrical integrity far longer than standard photocells

What Keeps Our Photocell Lighting Sensor Stable Under Extreme Heat and Sun Exposure?

In desert and tropical areas, outdoor lighting systems can experience ambient temperatures above 50 °C. At some places, UV radiation comes as an additional guest.

As per some studies, plastics suffer photo-oxidation when exposed to sunlight. They become brittle and crack over time. Ultimately, the moisture or dust ingress becomes likely.

Thermal & UV Protection Solutions

We deploy several engineering measures to combat these stresses:

- Heat-resistant PBT bases that maintain structural integrity at elevated temperatures and resist warping under sustained load. Below is a table showing a material performance comparison.

- UV-stabilised polycarbonate domes which retain optical clarity and light-sensing accuracy even after prolonged sun exposure.

- Advanced electronics, such as zero-cross switching technology, reduce relay arcing and thermal stress during dusk/dawn transitions in high-temperature environments.

| Material Type | Standard ABS Plastic | Generic Polycarbonate | Long-Join Engineering Blend |

| Max Operating Temp (°C) | 60 | 80 | 110 |

| UV Resistance Rating | Low | Moderate | High |

| Common Issues in Outdoor Use | Warping, color fading | Surface cracking | None observed after 1,000h UV test |

| Long-Join Solution | Replaced with heat-resistant PBT | UV-stabilized PC dome | Stable under desert exposure |

Tested for Deserts

Our designs are validated in harsh climate zones across the Middle East and tropical Asia. These regions are characterised by high ambient heat and solar intensity. Real-world field data shows our light sensor photocell switches maintain performance without increased maintenance or early failure.

How Do Our Light Sensors Survive Storms and Power Surges?

Outdoor lighting systems are exposed to lightning strikes and grid surges. These events generate transient voltages that easily exceed the ratings of standard control circuits. Without protection, light sensor switch relays and internal electronics may burn out from voltage spikes.

Our approach uses several critical protections to guard against these threats:

- Built-in surge protection, such as MOVs or arrestors, rated for up to 10 kA/20 kV transient events

- Dusk-to-dawn photocells are sealed to high IP ratings to prevent moisture ingress, which often leads to short-circuits

- High-durability relays and switching components are tested beyond 10,000 on/off cycles under load.

Proven Resilience

These design features deliver real-world results in locations with high exposure to unstable power networks. Compared to standard units that fail early under surge stress, our products offer lower maintenance and fewer replacements.

Further, here is a table outlining the industry average of surge and weather protection features vs Long-Join lighting controls.

| Protection Feature | Surge Protection | IP Rating | Relay Endurance |

| Industry Average | 4 kA / 10 kV | IP54 | 5,000 cycles |

| Long-Join Photocell | 10 kA / 20 kV | IP65 / IP66 | 10,000+ cycles |

| Test Standard | ANSI C136.10 | IEC 60529 | IEC 60947 |

| Key Benefit | Withstands lightning transients | Blocks rain and dust intrusion | Longer operational life |

What Certifications Prove Our Global-Standard Reliability?

Our photoelectric sensors deliver proven reliability through a suite of international certifications and market validations.

Key Compliance Standards

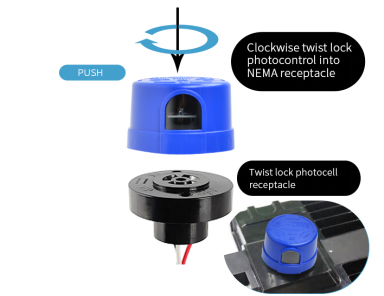

● ANSI C136.10

This defines the mechanical and electrical interchangeability of locking-type photocontrols and mating receptacles in roadway lighting equipment.

● UL 773

This is the recognised North American certification for locking-type photocontrols of the type used in outdoor luminaires.

● Zhaga Book 18

It ensures compatibility and interoperability of third-party components.

● CE and RoHS

These certifications ensure our products meet European safety and environmental compliance requirements.

Compliance with these standards signifies robust third-party testing for key performance criteria:

- Ambient temperature range

- Load carrying

- Switching cycles

- Ingress protection

- Mechanical durability and

- Compatibility with standard receptacles

Meeting these standards also eases global installation and procurement logistics for contractors and city planners. Major lighting industry players such as Philips and Tork specify the installation of components compliant with global standards. This demonstrates market trust in standards-based equipment.

Why Do Shanghai Long‑Join Electronics Photocontrol Receptacle Outperform Competitors in Harsh Conditions?

Engineering Excellence

Long-Join has 20 years of experience in lighting control manufacturing. The company operates a large factory covering an area of 38,000 m². Combined with automation, such a scale ensures the reliability of each unit.

Advantages for Clients

Long-Join serves major lighting markets globally, including North America, with a strong base of export capability. The company offers OEM/ODM customization. This allows clients to tailor the photocell to their specifications.

Additionally, Long-Join provides integration-ready solutions compatible with smart-city protocols. This includes:

Durability by Design

Rather than focusing on just one environmental stressor, Long-Join designs light photocell sensors with combined resistance against all climate odds. Because the product is engineered from the ground realities, it consistently outperforms generic photocells.

Further, here is a table comparing the performance of Long-Join products vs normal photosensors in various environments.

| Environment Type | Stress Factor | Competitor Performance | Long-Join Performance |

| Desert Climate | Heat + UV | Material softening after 6 months | Stable after 12 months |

| Coastal Areas | Salt Spray | Corrosion on terminals | Anti-corrosive coating |

| Thunderstorm Zones | Power Surges | Frequent relay damage | Surge protection 10 kA/20 kV |

| Industrial Areas | EMI Interference | False triggering | EMI-shielded design |

Final Words

Long-Join photocells prove their strength where others fail — in heat, salt, and storms. Their engineering delivers reliability that stands up to every environment. For projects needing trusted outdoor lighting performance, Chi-Swear offers genuine Long-Join photocontrollers backed by expertise and consistent quality.

External Links

- https://en.wikipedia.org/wiki/Photo-oxidation_of_polymers

- https://www.ansi.org/

- http://www.julixing.com.cn/en/new/new-58-907.html

- https://www.zhagastandard.org/?view=article&id=64:book-18&catid=10

- https://en.wikipedia.org/wiki/CE_marking

- https://en.wikipedia.org/wiki/RoHS

- https://en.wikipedia.org/wiki/Zigbee

- https://en.wikipedia.org/wiki/Narrowband_IoT

- https://en.wikipedia.org/wiki/LoRa