Outline

- Introduction

- What Makes Lighting Demand Smarter and More Flexible Connectors?

- Why Does the JL-700W2 Photocontroller Use an 8-Hole Architecture Instead of the Standard 4?

- How Does Dual Entry per Pin Improve Wiring Flexibility?

- How Does the 8-Hole Design Support Multi-Node Smart Lighting Architectures?

- How Does the JL-700W2 Improve Pass-Through Reliability During Maintenance?

- How Does an 8-Hole Receptacle Reduce Installation and Maintenance Costs?

- How Do 8 and 4-Hole Zhaga Receptacles Compare in Real Use Cases?

- What Additional Advantages Does the JL‑700W2 Offer Beyond the Extra Holes?

- Why Is the JL‑700W2 the Better Choice for Future‑Proof Smart Lighting Systems?

- Final Words

Why would a Zhaga receptacle need eight wire holes when the standard only uses four? Street lighting is changing fast. So are the connectors that power it.

Modern luminaires no longer rely on a single lighting control. They now host sensors and intelligent controllers. The JL-700W2 was built for this new reality. It’s an 8-hole design that:

- Gives installers more flexibility

- Supports multi-device setups and

- Cuts wiring costs

This article explains the logic behind it and why cities prefer this upgraded approach.

What Makes Lighting Demand Smarter and More Flexible Connectors?

Smart outdoor lighting is transforming into a modular and connected ecosystem. Zhaga Book 18 defines a standardised interface for sensing and communication modules.

But the traditional 4-hole wiring of Book 18 limits flexibility: only single wires per pin, and fewer opportunities to expand.

Enter the JL-700W2: built to support newer, high-flexibility architectures. It lets luminaire makers design for more than just a photocell. Below is a table showcasing JL-700W2 pin functions and wire types.

Modern smart cities demand more. They need multiple IoT devices — motion sensors, environmental probes, DALI nodes — all drawing power or data from a single interface.

That means simpler wiring, fewer addons, and real plug-and-play interoperability.

| Pin | Standard Function | Recommended Wire Type | Max Current |

| 1 | V+ (24 V) | 18–16 AWG, stranded | 5 A |

| 2 | DALI / GND | 20–18 AWG, shielded | 0.5 A |

| 3 | DALI + | 20–18 AWG, shielded | 0.5 A |

| 4 | I/O (general) | 18–20 AWG, flexible | 2 A |

Why Does the JL-700W2 Photocontroller Use an 8-Hole Architecture Instead of the Standard 4?

Standard Zhaga Book 18 receptacles use 4 pins:

- +24 V (aux power)

- DALI / ground

- DALI +

- I/O (general purpose)

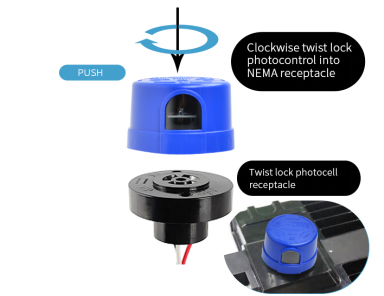

The JL-700W2 doubles that with an 8-hole, dual-entry design. This means:

Four pins × two holes = eight wire entries

This “S2 dual-entry” setup lets each pin carry two wires. One wire might power a primary controller, while the second passes through to another device.

For installers, that means more wiring versatility. You don’t need extra terminal blocks. You can set up pass-through or parallel connections natively.

How Does Dual Entry per Pin Improve Wiring Flexibility?

Dual-entry means each of the four Zhaga-Book-18 pins has two wire entries instead of one. In traditional bases, you get a single hole per pin — that restricts you to one connection each. But with dual-entry, you can route two wires for every contact.

This enables direct pass-through wiring. One cable can supply the controller, while the other continues to another node.

This is all done without using external terminal blocks. This makes wiring cleaner and far less cluttered. Installers don’t need extra junctions or bulky add-ons.

For OEMs and field teams, that’s a big win. You reduce parts, save on labour, and simplify the layout. Maintenance becomes easier, too — you can photocell lighting sensor modules without messing up the core wiring.

How Does the 8-Hole Design Support Multi-Node Smart Lighting

Smart luminaires today often need more than just a light sensor switch. They carry a main controller plus an auxiliary device — think motion sensor, radar, or environmental probe. The JL-700W2’s 8-hole design lets you wire both in parallel, using the same receptacle.

With its “one in, one out” layout, you can feed power or DALI to the first node and pass the rest straight through to the second — no extra junctions needed. This clean pass-through wiring keeps things simple and compact.

Real-world example

You mount a Zhaga dusk-to-dawn photocell on top of a streetlight and a side-mounted motion sensor. Thanks to the dual-entry design, both devices plug into the same Zhaga interface, run their wiring through, and function independently — all while sharing that single receptacle.

How Does the JL-700W2 Improve Pass-Through Reliability During Maintenance?

In city lighting networks, keeping the DALI loop or 24 V rail intact is critical. Interruptions mean loss of communication or even a power failure.

The JL-700W2’s dual-entry design lets you remove a controller without opening or breaking the circuit. That means even during a hot-swap, power and DALI signals stay live.

Field technicians can change the faulty node, and the rest of the network remains stable. This boosts uptime and lowers maintenance risk.

Plus, you don’t need extra wiring or terminal blocks — everything stays routed cleanly through the same receptacle, making fleet-wide maintenance faster and more reliable.

Here is a table comparing JL-700W2 specifications vs industry standards of photocells for various environmental conditions.

| Parameter | JL‑700W2 Specification | Industry Standard Comparison |

| Operating Temp | -40 °C to +70 °C | Zhaga Book-18: -40 °C to +60 °C |

| Ingress Protection | IP66 (with controller) | Standard receptacles: IP65 |

| UV Resistance | High, reinforced polymer | Standard: Medium |

| Vibration | 5–500 Hz, 2 g | Standard: 1 g |

How Does an 8-Hole Receptacle Reduce Installation and Maintenance Costs?

The JL-700W2 removes the need for external terminal blocks by allowing two wires per contact.

Fewer parts mean fewer purchase costs and fewer failure points. The dual-entry reduces on-site wiring time. Installers make fewer junctions and finish jobs faster.

Tool-free module swaps become practical. Technicians can hot-swap controllers without extra tools or rewiring.

OEMs benefit too. The compact, gasket-integrated receptacle simplifies assembly and reduces the bill of materials.

Compared with TE’s Endurance S2 (two-wire per contact), JL-700W2 delivers similar wiring advantages while prioritising compact sealing and OEM-friendly integration.

How Do 8 and 4-Hole Zhaga Receptacles Compare in Real Use Cases?

Here’s a detailed comparison:

| Feature | 4-Hole Receptacle | 8-Hole (Dual-Entry) Receptacle |

| Wires per Pin | 1 wire per pin | 2 wires per pin, allowing pass-through |

| Wiring Complexity | Simpler single-point connections, but limited extension | More flexible; enables daisy-chain or parallel wiring with less clutter |

| Multi-Node Support | Suited for a single controller or sensor only | Built for main + auxiliary nodes — e.g., sensor + controller |

| Cost Implications | Low initial cost, but requires extra terminals for complex setups | Saves on external terminal blocks and labour; reduces BOM complexity |

| Target Applications | Basic streetlights with one Zhaga module | Smart city fixtures with DALI, sensors, or multiple IoT devices |

What Additional Advantages Does the JL‑700W2 Offer Beyond the Extra Holes?

- The JL‑700W2 has a compact body with an integrated gasket, giving IP66 sealing when a controller is mounted.

- It supports mounting on the top, side, or bottom of a luminaire — so OEMs get great flexibility.

- It’s also future‑ready for D4i, meaning it can support smart city architectures under the DALI‑Alliance standard.

- The design is optimised for high-volume OEM manufacturing: fewer parts and a streamlined build process.

All this gives you a sealed, flexible, and scalable base — not just a connector.

Why Is the JL‑700W2 the Better Choice for Future‑Proof Smart Lighting Systems?

In short, the JL‑700W2 transforms a simple Zhaga receptacle into a multi-device wiring hub. With dual-entry wiring, you can power a main controller and a side-node from the same base.

Its IP66 sealing, flexible mounting, and D4i compatibility make it ideal for smart city use. For cities and utilities, this means fewer spare parts, simpler installs, and easier maintenance. For luminaire manufacturers, it cuts BOM complexity and accelerates production.

If you’re building with an eye to the future — with IoT sensors, DALI nodes, or future‑proof upgrades — the JL‑700W2 clearly gives more value than a standard 4‑hole receptacle.

Final Words

The JL‑700W2 redefines Zhaga receptacles with 8-hole dual-entry wiring. This offers flexibility and multi-node support. Its compact, gasketed design ensures durable and future-proof smart lighting installations. For high-quality Long-Join photocontrollers and reliable Zhaga components, Chi-Swear remains a trusted supplier, providing products built for efficiency, durability, and OEM-friendly integration.