Outline

- Introduction

- What Makes Customers Choose Different Voltage Types for Photocell Switches?

- Where Are High-Voltage AC Photosensors Commonly Used?

- Why Do Customers Prefer High-Voltage AC Light Sensors for Public and Utility Projects?

- Where Are Low-Voltage DC Photoelectric Sensors Typically Used?

- Why Do Customers Choose Low-Voltage DC Photocontrol Receptacles for Solar and Off-Grid Systems?

- What Industry Standards Influence Voltage Selection for Photocells?

- How Do Real-World Projects Decide Between AC and DC Light Photocell Sensors?

- What Is the Key Takeaway for Lighting Buyers and Procurement Teams?

- How Does Long‑Join Support All Voltage Requirements for Global Lighting Projects?

- The Bottom Line

Why do consumers need light photocells in so many different voltages?

The answer is simple. Lighting systems don’t run on the same power everywhere. All use different power sources.

This guide breaks down why those voltage differences exist—and how choosing the right one protects reliability, safety, and cost.

What Makes Customers Choose Different Voltage Types for Photocell Switches?

Customers pick different photocell lighting sensor voltages mainly because lighting power systems vary strongly by application and environment.

Many installations connect directly to the electric grid. In those cases, photocells must match the grid voltage. For example, for large municipal or industrial networks, this includes

- 120 V

- 208/240 V

- 277 V, or

- 347–480 V

Using an outdoor photocell light sensor rated for full grid voltage ensures reliable switching.

Use of a low-voltage photocell on a high-voltage circuit may cause internal components to overheat. This may turn into a fatal safety hazard.

On the other hand, many lighting systems run on local DC power. These systems typically use

- 12 V DC

- 24 V DC

- 48 V DC

A DC photocell sensor rated for such voltages allows direct integration without inverters or extra conversion. Low-voltage DC also helps reduce wiring losses and increases safety in smaller or off-grid installations.

Further, here is a table comparing the advantages of AC vs DC photocells.

| Feature | AC Photocells (120–480 V) | DC Photocells (12/24/48 V) |

| Installation Speed | Fast for grid-connected projects | Moderate; needs battery matching |

| Safety | Requires proper insulation | Safer at low voltage |

| Energy Loss | Minimal in large grids | Low inverter losses in DC systems |

| Maintenance | Low for standard AC networks | Low if integrated properly with the DC system |

| Cost | Lower wiring cost for large deployments | Lower component cost for off-grid systems |

Where Are High-Voltage AC Photosensors Commonly Used?

High-voltage AC lighting controls match standard power systems used in many regions. For example:

- 120 V is common in U.S. residential buildings.

- 208–277 V (part of a three-phase or commercial/industrial supply) is widely used for municipal lighting, commercial buildings, and public lighting projects.

- 480 V supplies heavy-duty industrial zones, factories, large commercial buildings, and large-scale street/area lighting networks.

In short, high-voltage AC photocontrollers are used wherever the power supply is from the main electric grid — from houses to industrial complexes. That is why many grid-connected lighting projects need photocells rated for 120 to 480 V.

Why Do Customers Prefer High-Voltage AC Light Sensors for Public and Utility Projects?

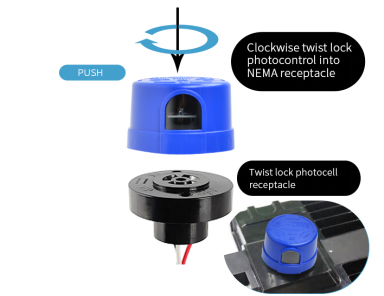

Customers choose high-voltage AC photocells because they fit directly into existing grid infrastructure. These units connect straight to utility power lines without extra parts. That means:

- No transformers required — fewer components to buy and install.

- Simpler wiring — reducing labor time and material cost.

Electrical systems that tap directly into grid circuits don’t need a voltage step-down, which speeds up installation and lowers project cost. In large citywide lighting deployments, this simplicity matters a lot. It keeps labor and material costs down for contractors.

High-voltage AC photocells also deliver long-term reliability in grid systems. They handle full line voltage safely and consistently when properly rated, which is why utility and municipal lighting networks depend on them for stable dusk-to-dawn switching.

When matched to grid voltage, these photocells reduce the risk of premature failure or wiring faults — a key priority in public lighting standards.

Where Are Low-Voltage DC Photoelectric Sensors Typically Used?

These light sensors find use wherever lighting runs off batteries. Whether attached to solar panels or other DC sources. Typical applications include:

● 12 V DC

Small solar kits, garden lights, security lights, RVs, boats, and remote outdoor lighting using battery banks.

● 24 V DC

Widely adopted for solar-powered streetlights and industrial control-system lighting. Many DC street-light fixtures support 24 V input for straightforward integration with solar battery systems.

● 48 V DC

Common in telecom towers, remote microgrid installations, and off-grid street or area lighting. 48 V systems allow longer cable runs with lower current losses. This makes them ideal for large battery banks and remote setups.

In many regions where grid electricity is unreliable or unavailable, these DC photocells are essential for operation using solar or battery systems. They enable entirely off-grid lighting solutions with minimal infrastructure.

Why Do Customers Choose Low-Voltage DC Photocontrol Receptacles for Solar and Off-Grid Systems?

Because they pair directly with battery systems, this means you avoid inverter losses entirely. That improves overall energy efficiency.

DC systems at 12 V, 24 V, or 48 V offer much higher electrical safety than high AC. This also reduces the risks of shock and fire.

For solar and hybrid lighting, DC photocells integrate more cleanly. The solar panel, battery, controller, and fixture all run on DC — no need for complex conversion.

In telecom sites and microgrids, DC systems simplify design and maintenance. They reduce component count and ensure stable dusk-to-dawn switching without relying on unstable grids.

What Industry Standards Influence Voltage Selection for Photocells?

Industry norms and regional power standards shape which photocell voltages get used.

- The telecommunications industry widely standardizes on 48 V DC. Telecom hardware and backup batteries are built around this level.

- Solar-lighting OEMs often follow 12 V or 24 V DC standards for streetlights and small solar setups. Those voltages suit battery-based systems without needing inverters.

- In “smart city” projects, it’s common to mix AC grid-powered poles and DC solar-powered poles — so photocells must match both systems depending on the pole type.

- Regional grid standards also matter. In North America, depending on installations, lighting circuits commonly use:

- 120 V

- 208/240 V

- 277 V

- 347 V, or

- 480 V AC.

Because of these standards, manufacturers and contractors often stock photocells across a wide voltage range. This ensures compatibility whether a project uses DC solar systems, telecom setups, or conventional grid power. Here is a table outlining key industry standards regarding photocell applications.

| Industry / Standard | Voltage Standard | Example Applications |

| Telecom | 48 V DC | Towers, remote monitoring stations |

| Solar streetlight | OEMs 12/24 V DC | Off-grid streetlights |

| North American grid | 120–480 V AC | Residential, commercial, municipal |

| Canada commercial grid | 347 V AC | Large office/shopping areas |

| Smart city hybrid projects | AC + DC mix | Grid-connected + solar poles |

How Do Real-World Projects Decide Between AC and DC Light Photocell Sensors?

Projects pick the photo switch sensor voltage based on what power system is available or planned.

- In many US municipal and utility networks, street-lighting circuits run on 120 V or 277 V AC. That makes AC-rated photocells the natural choice.

- Solar street lights are common in parts of Africa. They also find application in other regions with limited grid reach. These systems use 12 V and 24 V DC. Thus, they rely on a DC photocell with low voltage.

- For remote telecom towers and backup-powered sites — especially where battery banks are used — 48 V DC is the standard power base. Photocells matching 48 V are used there.

- In European or globally diversified EPC projects, there is sometimes a hybrid mix. 230 V AC for grid-connected luminaires, and 24 V for solar or backup-powered poles. Contractors choose accordingly, matching photocell voltage to each pole’s power source.

In practice, engineers and EPC contractors check the infrastructure (grid or battery), then specify photocells that match that voltage — ensuring both safety and performance for each deployment. The table below shows the recommended photocell voltage according to project types.

| Project Type | Recommended Voltage | Reason |

| Municipal street lighting | 120–277 V AC | Direct grid connection, lower installation cost |

| Solar streetlight network | 24 V DC | Matches solar battery systems |

| Telecom tower lighting | 48 V DC | Long cable runs, low energy loss |

| Residential garden/park | 12 V DC | Safer low-voltage operation |

| Hybrid city project | AC + DC mix | AC poles on the grid, DC solar backup |

What Is the Key Takeaway for Lighting Buyers and Procurement Teams?

Choosing the right outdoor light sensor switch voltage is critical for system performance. AC and DC applications serve very different needs.

- AC (120–480 V) works best for conventional grid-connected lighting. Municipal streets, commercial campuses, and industrial zones rely on AC‑rated photocells. They connect directly to the grid, reducing the need for extra components.

- DC (12/24/48 V) is ideal for solar, telecom, and off-grid systems. Direct battery compatibility avoids inverter losses. Low voltage ensures safer operation in public spaces.

For buyers and procurement teams, voltage selection equals system compatibility and reliability. Matching the photocell to the power source saves costs and ensures long-term operation.

How Does Long‑Join Support All Voltage Requirements for Global Lighting Projects?

Long‑Join offers photocells for every voltage requirement. Their catalogue ranges from 12 V DC for small solar or off-grid systems to 480 V AC for industrial and municipal grids.

They provide custom solutions tailored to specific needs. Each project receives the photocell voltage that matches its infrastructure, ensuring safe and efficient operation.

Key benefits include:

- Compatibility with AC and DC systems worldwide.

- Reduced installation errors with correct voltage matching.

- Support for hybrid lighting networks mixing grid and battery-powered poles.

For project planners and procurement teams, Long‑Join helps identify the right photocell quickly. Contacting them ensures your lighting system uses the correct voltage, improving reliability and performance.

The Bottom Line

Choosing the right photocell voltage ensures safety and long-term reliability. AC models suit grid-powered lighting, while DC models work best for solar and off-grid systems. For dependable photocells across all voltages, Chi-Swear offers Long-Join solutions tailored to every project. Contact us to find the perfect match for your lighting needs.

2 Responses

Normally I do not learn article on blogs, but I would like to

say that this write-up very forced me to take a look at and do so!

Your writing style has been surprised me. Thanks, very nice post.

Appreciate your feedback—happy it added value