(Customer – Requested)

Here We Explain in Detail the Differences between the Two, the Specific Meaning of the Customer’s Wiring Method and the Reasons Behind It:

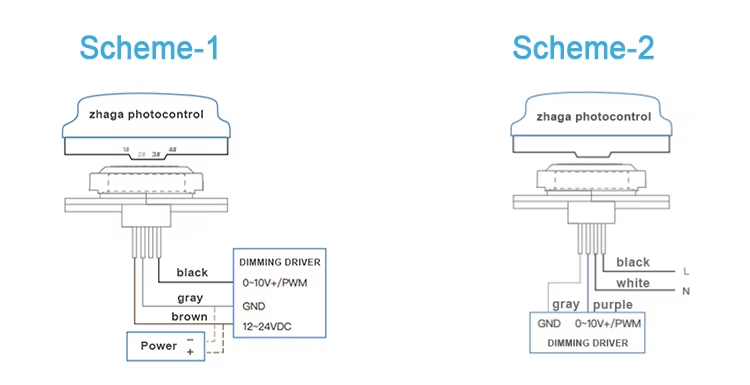

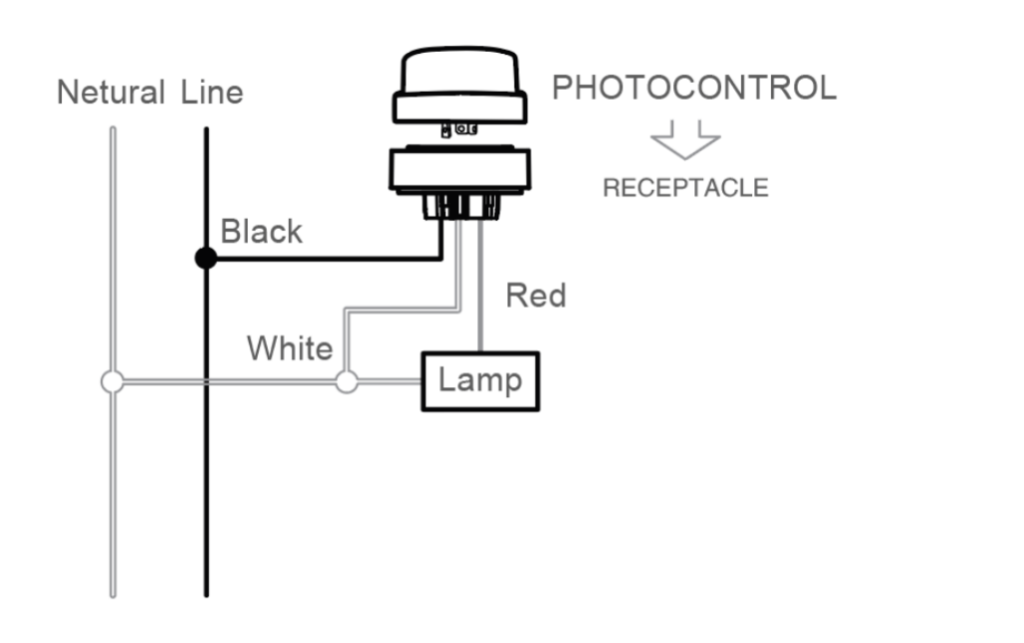

I. Our Standard 3 – Wire Wiring Method of Photocell (ANSI Standard)

The ANSI – standard wiring method commonly used for our Long – Join photocell products consists of 3 wires:

| Wire Color | Function Description | Wiring Terminal |

|---|---|---|

| Black | Power Input (Line) | Connect to the live wire of the power supply |

| White | Neutral Line (Neutral) | Connect to the neutral wire of the power supply |

| Red | Output Load Wire (Load) | Connect to the live wire of the load (lighting fixture) |

In this standard wiring method, the input and output share one neutral wire (the white Neutral wire).

II. Customer – Requested – Wire Wiring Method (Black for Li, White for N; Red for Lo, White for N)

The customer’s wiring method uses 4 wires and is a “completely separated input – output” wiring method:

| Wire Color | Function Description | Wiring Terminal |

|---|---|---|

| Black | Input Live Wire (Line In) | Connect to the live wire input of the AC power supply (Li) |

| White | Input Neutral Wire (Neutral In) | Connect to the neutral wire input of the AC power supply (Ni) |

| Red | Output Live Wire (Line Out) | Output to the live wire of the load (Lo) |

| White | Output Neutral Wire (Neutral Out) | Output to the neutral wire of the load (No) |

This method is called “complete input – output isolation”, meaning that the live and neutral wires of the input and output ends are completely independent and not shared.

III. Specific Differences

| Specific Difference Points | Our Commonly Used 3 – Wire Method | Customer’s 4 – Wire Isolation Method |

|---|---|---|

| Neutral Wire (N) | Shared for input and output | Independently separated for input and output |

| Safety | General safety | Higher safety level |

| Application Scenarios | Conventional outdoor lighting, simple streetlights | More rigorous outdoor public lighting projects |

| Installation Complexity | Simple and easy to wire | Slightly more complex, with one additional neutral wire |

| Difference in Product Internal Structure | Can be controlled by a simple single – pole single – throw relay | Requires additional wiring terminals or a dedicated relay inside |

IV. Reasons Why Customers Adopt the 4 – Wire Method of photocell

Customers specifically request the 4 – wire (2 inputs + 2 outputs) wiring method usually for the following reasons:

1. Higher Safety Requirements:

- Regulations in some countries or regions where customers are located require that the input and output circuits must be completely isolated.

- Isolating the input and output circuits can avoid equipment damage or electric shock risks caused by neutral wire breakage or misconnection.

2. Higher Reliability and Equipment Protection:

- The completely separated input – output wiring method is conducive to providing better electrical protection.

- In case of a fault, it is easier to detect and determine the problem, and clarify the responsibility.

3. Specific Certification Requirements:

- Customers may specifically require the use of this input – output isolation scheme when applying for certain high – level safety certifications (such as specific UL certification standards in North America or government/municipal streetlight project specifications) to meet specific certification requirements.

4. Avoiding Problems Caused by Sharing the Neutral Wire:

- For example, in large – scale public lighting systems, unbalanced neutral wire loads or voltage differences may pose potential safety hazards, and the isolated wiring method can effectively avoid such problems.

V. Why Our Products Currently Use 3 – Wires

- Standardization Considerations: Wiring methods with 3 wires are commonly accepted by standards such as ANSI C136.10/UL773 and have been widely used. The wiring is simple and easy to understand.

- Cost Considerations: The product structure with 3 – wire wiring is simple. Only a single – pole single – throw relay is needed inside, which results in a low cost and makes the product more competitive in the market.

- Wide Application Range: The vast majority of markets and customer projects do not strictly require complete isolation. 3 – wire products are sufficient to meet the needs of most application scenarios.

However, with the changes in market demands and regulations, for high – end projects or special customer needs, we may consider launching 4 – wire completely isolated products in the future to cover more market demands.

VI. Product Realization Methods (if Customers Must Have 4 – Wires)

If customers insist on this wiring method, the factory needs to make corresponding adjustments:

- Relay Configuration Adjustment: A double – pole double – throw relay (DPST Relay) must be used to cut off or connect the live wire and the neutral wire simultaneously.

- Internal Circuit Adjustment: The live and neutral wires of the input end enter the input terminals of the relay completely independently, and the output end is then separately output by the relay.

- Wiring Terminal Adjustment: Provide independent input and output wiring terminals or wires inside the product.

VII. Suggestions for Communicating with Customers

- First, understand the real reasons why customers insist on the 4 – wire method, and confirm whether it is due to regulatory requirements, project requirements, or customer habits.

- Clearly inform customers that the 4 – wire solution will increase costs compared to the 3 – wire solution, and the price may rise accordingly.

- If customers confirm that they must have 4 – wires, product adjustment and design can be arranged according to the project volume and long – term cooperation prospects.

VIII. Summary (for Sales to Communicate with Customers)

The core of the customer’s request for the 4 – wire (2 AC inputs, 2 AC outputs) method is to achieve complete isolation of the input and output circuits, so as to improve the safety and reliability of the product. Our current standard ANSI products use the 3 – wire method, which is a conventional wiring method with the input and output sharing the neutral wire and has been widely used in the market.

It is recommended to clearly communicate with customers about their specific needs and regulatory requirements to determine whether special customization is required or whether to use our existing standardized and mature products.

The above is a detailed description of the differences between the 4 – wire method and the 3 – wire method and the reasons behind them. If you have any other questions or need further technical support, please feel free to ask.