Outline

- Introduction

- Understanding the Photocell Procurement Process

- Common Challenges in Photocell Procurement

- Supplier Reliability

- Production and Supply Chain Disruptions

- Regulatory and Compliance Hurdles

- Technological Compatibility

- Strategies to Overcome Procurement Challenges

- Supplier Vetting and Relationship Management

- Diversifying the Supply Base

- Inventory Management

- Leveraging Technology and Automation

- How To Find A Reliable Photocell Supplier

- The Bottom Line

We see and use photocells every day. They control lighting, trigger alarms to increase safety and provide power for some calculators. As the need for energy-efficient devices increases, photocells have also witnessed a boost in demand.

However, the current global supply chain landscape presents challenges for companies seeking to source photocells on time. The intricate network of international manufacturers, distributors, and transportation providers can introduce delays that disrupt project timelines and impact business efficiency.

This article will discuss common issues with photocell procurement and provide practical strategies to navigate them, ensuring your projects receive the necessary components when needed.

Understanding the Photocell Procurement Process

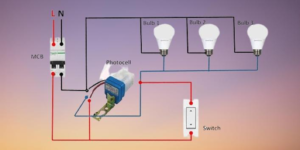

Photocells are electronic devices that convert light energy into electrical current. Their applications are diverse in almost every sector.

The typical procurement process starts with identifying specific photocell requirements like sensitivity, spectral range, and housing type. Companies then source qualified suppliers, negotiate pricing and lead times and place purchase orders. Key stakeholders include engineers specifying the photocell needs, procurement teams managing supplier relationships, and logistics providers ensuring timely delivery.

Common Challenges in Photocell Procurement

Securing on-time delivery of photocells requires navigating a complex landscape filled with potential roadblocks. This section explores the key hurdles companies face, starting with supplier reliability.

Supplier Reliability

Finding reliable suppliers with consistent production capacity is crucial for timely project completion. However, supplier reliability goes beyond manufacturing capabilities. Issues like quality control problems, dependence on a single supplier, or limited communication can all lead to delays.

Unforeseen production delays or recalls from suppliers can greatly interfere with your project schedules, affecting delivery times and probably also the cost of a project. The key solution that helps in minimizing these risks includes forming good relationships with suppliers while ensuring that you have more than one supplier.

Production and Supply Chain Disruptions

With ongoing conflicts, supply chain disruption could be a major hurdle. Material shortages or unexpected equipment malfunctions can delay the manufacturing process, and the increasingly complex global supply chain can further complicate the crisis.

International transportation issues, issues with sea trade, and constantly changing trade regulations can all lead to extended lead times. Additionally, natural disasters or political instability can significantly disrupt the flow of goods. This all severely impacts photocell availability and delivery timelines.

Regulatory and Compliance Hurdles

Photocells, depending on their application and technology, may be subject to specific regulations. These regulations can vary by region and focus on aspects like safety, electromagnetic compatibility (EMC), or environmental impact.

Failure to comply with these regulations can lead to delays as photocells undergo additional testing or certification. Understanding the relevant regulations and ensuring suppliers have the necessary certifications is crucial for avoiding unexpected delays at customs or during project inspections.

Technological Compatibility

Securing on-time delivery is only half the battle. The photocells you receive also need to function flawlessly within your specific application.

There are different types of photocells. If you choose the wrong one, it can create several issues in your project. For instance, incorrect detection of light can make automatic systems to malfunction. This can lead to more complications in terms of raising complexity levels as well as possibly causing delays for the completion date.

Furthermore, improper housing types might not be suitable for the environmental conditions where the photocell will be installed, leading to premature failure and the need for replacements. By thoroughly specifying your technical requirements during the procurement process and ensuring your chosen supplier offers compatible photocells, you can avoid costly delays and ensure project success.

Strategies to Overcome Photocell Procurement Challenges

You can never defy challenges in any procurement process. However, there are some effective strategies companies can implement to overcome these issues.

Supplier Vetting and Relationship Management

The cornerstone of a smooth photocell procurement process lies in selecting reliable suppliers and fostering strong relationships with them. This involves a thorough vetting process that evaluates factors like production capacity, quality control procedures, and past performance.

Besides choosing a reliable supplier, ongoing communications are key. They help establish clear expectations about lead times and order quantities. This eventually boosts trust and transparency, allowing you to proactively address any potential issues.

Diversifying the Supply Base

Dependency on a single supplier can make you vulnerable to unexpected disruptions. Diversifying your supply base offers several benefits. It mitigates risk by ensuring you have alternative sources in case of production slowdowns or supplier issues. Additionally, it can foster competitive pricing and potentially lead to shorter lead times as you negotiate with multiple vendors.

To effectively diversify, explore established marketplaces and industry publications to identify reputable photocell suppliers. Implement a qualification process similar to your initial vetting, evaluating their capabilities and compatibility with your needs. By establishing relationships with multiple reliable suppliers, you gain greater control over your procurement process and ensure a more stable flow of photocells for your projects.

Inventory Management

Accurate demand forecasting is crucial for maintaining optimal photocell inventory levels. By analyzing past usage patterns and anticipating future project needs, you can avoid stockouts that lead to delays.

Exercising safety stock policies is an additional way of protecting yourself from sudden breakdowns in the supply chain. Through efficient stock control, you can anticipate likely slowdowns and make certain that you are equipped with whatever will help in the ongoing implementation of projects without any stoppage.

Leveraging Technology and Automation

Modern procurement software can streamline the photocell procurement process. These tools can centralize supplier information, facilitate communication, and automate tasks like order placement and tracking.

Additionally, Using automatic tools to track orders can tell you exactly how long it takes to fulfill them and if there might be any holdup. By using technology, you can work faster and fix any problems that could prevent on-time delivery before they happen.

How To Find A Reliable Photocell Supplier

While this article explores various strategies for navigating photocell procurement, identifying reliable suppliers remains a critical first step. Chiswear stands out as a leading provider of photocells, offering a comprehensive selection, exceptional quality, and a commitment to on-time delivery.

Their established industry presence, robust manufacturing capabilities, and focus on customer satisfaction make them a trusted partner for all your photocell needs. The following sections delve deeper into the strategies for overcoming procurement challenges and ensuring a smooth flow of photocells for your projects.

The Bottom Line

Ensuring on-time delivery of photocells requires proactive management and strategic planning to navigate common procurement challenges. For reliable and timely photocell procurement, consider Chiswear products. Known for their quality and dependable delivery, Chiswear can help keep your operations running smoothly.