Outline

- Introduction

- Flexibility and Adaptability

- Improved Environmental Protection

- Polyvinyl Chloride

- Polyethylene

- Polyurethane

- Power and Signal Transmission

- Electric Power Supply

- Smart Control Integration

- Safety and Security

- Electrical Safety

- Interference Reduction

- Maintenance and Upgradability

- Ease of Maintenance

- System Scalability

- Cost Efficiency and Market Trends

- Budget Considerations

- Market Future

- The Bottom Line

Photo control receptacles are the backbone of modern-day smart lighting systems. They sense the ambient light level, or in some cases, the operational needs, and manage the lighting accordingly. This effectively reduces energy waste and improves safety.

However, their effectiveness depends on secure and reliable connectivity, and that is where the cable wires come to the scene. These wires link photocontrol receptacles and power sources, enabling smooth electrical transmission and smart control integration. The right cable selection impacts durability, performance, and adaptability in different environments.

This article discussed the dependability of photocells on cable wires, highlighting their various features that affect these modern lighting systems.

Flexibility and Adaptability

Whether it’s about cost savings or sustainability, energy efficiency trends are on a perpetual rise. As a result of this, the use of photocell is not limited to streetlights only; it is increasing in both industrial and domestic applications. Cable wires, against this backdrop, are essential for tailored installations of photo controls, especially outdoors.

Complex installation environments require careful planning of cable routes. Cable wire’s flexibility makes it possible to route the cables around obstructions such as buildings and trees to achieve optimal placement of sensors. This flexibility is important for consistent lighting performance across different environments.

For high-end mapping, applying path-planning algorithms is an efficient method. This helps to create effective cable layouts in complex environments to achieve safe and efficient connections.

Improved Environmental Protection

In the outdoor environment, photo sensors are exposed to tough conditions such as high temperatures, humidity, and UV radiation. For reliable performance and longer lifespan in these environments, special cables are required.

The following are some widely used insulation materials that provide reliability for cables in harsh environments.

Polyvinyl Chloride

PVC is extensively employed for cable jackets because of its superior weather resistance and good insulation characteristics. It is effective in protecting cables from moisture and UV radiation, thus being applicable to a wide range of outdoor uses.

Polyethylene

These are well-recognized for their superior electrical characteristics. Its low dielectric constant makes it suitable for high-frequency applications.

Polyurethane

PU comes with high elasticity and superior abrasion resistance. This is highly effective against oils, chemicals, and mechanical stress, which makes it suitable for applications where cables are exposed to constant movement or physical shock.

Proper cable material selection is important to ensure the functionality and integrity of the light sensor switch. Using cables with PVC, PE, or PU jackets ensures improved environmental protection and the longevity of your lighting systems.

Power and Signal Transmission

Electric Power Supply

The importance of reliable power transmission for any electronic needs is not emphasized; it’s critical. Photocontrol receptacles, such as the ANSI photocells, are designed to operate within a voltage range of 105-305 VAC.

Cable wires that can support these voltage requirements prevent power fluctuations, resulting in an increased life span of the complete lighting system. On the contrary, the low-quality cable installation can result in malfunctioning of the lighting control devices.

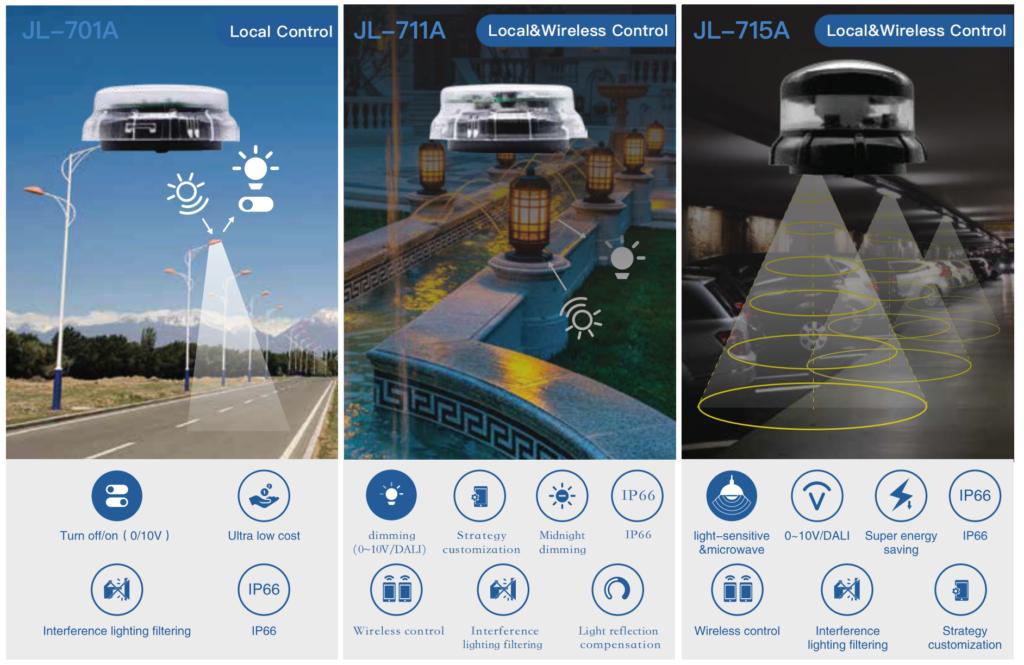

Smart Control Integration

In modern lighting systems, cable wires do more than just power transmission. They also facilitate communication between smart devices.

Protocols like DALI use a basic two-wire connection to transport power and communication signals. This setup thus allows for dynamic adjustments, making centralized control of the lighting devices possible.

Choosing the appropriate cabling that supports these protocols is vital for the successful implementation of smart lighting solutions.

Safety and Security

Electrical Safety

Proper insulation acts as a barrier against electrical leakage and ensures that electrical currents flow only along designated paths. This minimizes the risk of accidental contact and short circuits.

For insulation, the above-mentioned choices, like Polyvinyl Chloride, Polyethylene, and Polyurethane, are all good to go.

Interference Reduction

Electromagnetic interference in cable systems is another important concern that must be addressed. By incorporating conductive layers, such as foil or braided shields, cables can block external electromagnetic fields that may disrupt signal integrity.

This shielding ensures the stable performance of light photocell systems by maintaining clear and reliable signal transmission that is free from external noise.

Maintenance and Upgradability

Ease of Maintenance

Photocontrol receptacles designed with twist-lock mechanisms simplify maintenance by allowing quick replacement of faulty components and not the complete unit. This design innovation reduces downtime and maintenance costs.

System Scalability

The adoption of standardized interfaces, like the NEMA 7-pin configuration, enhances system scalability by providing a universal platform for integrating advanced control modules.

This standardization allows for seamless upgrades and expansions. As a result, lighting systems can evolve with technological advancements without requiring complete overhauls, ensuring long-term adaptability and efficiency.

Cost Efficiency and Market Trends

Budget Considerations

For large-scale installations, cost-effective solutions are essential. Utilizing standardized components, such as ANSI C136.10 compliant photocell sensors, can significantly reduce expenses.

These components are widely available and compatible with various lighting systems, streamlining procurement and maintenance processes. Additionally, products like LongJoin’s shorting cap offer a budget-friendly option for managing lighting circuits collectively, enhancing operational efficiency without compromising quality.

Market Future

The smart lighting market is experiencing rapid growth, driven by the integration of Internet of Things (IoT) technologies. Valued at approximately USD 15.8 billion in 2024, the market is projected to grow at a CAGR of 19.3% from 2025 to 2034.

This expansion is fueled by smart city initiatives and the increasing adoption of smart home technologies. Lighting controls are evolving to support advanced functionalities, including remote monitoring and adaptive lighting controls, positioning them as pivotal components in modern, connected lighting infrastructures.

The Bottom Line

Photocontrol receptacles rely on high-quality cable wires for flexibility, durability, and efficient power and signal transmission. Choosing the right cables enhances system reliability, safety, and long-term cost efficiency. For dependable photocontrol solutions, Chi-Swear offers high-performance products designed for durability in demanding environments. Their expertise ensures reliable and future-ready lighting control systems.