Outline

- Introduction

- Purpose of Gold-Plating Contact Blades

- Enhanced Conductivity

- Oxidation and Corrosion Resistance

- Contact Stability

- Electromagnetic Interference (EMI) Reduction

- Advantages of Gold-Plated Contact Blades in Photo Controls

- Technical Requirements and Challenges

- Optimal Gold Thickness

- Precision in Electrical Connections

- Environmental Adaptability

- Future Trends in Gold Plating Technology in Photo Controls

- Eco-Friendly Practices

- Nanotechnology Integration

- Advancements in Manufacturing Precision

- Cost Reduction Strategies

- Final Words

The quest for sustainable options is on a perpetual rise. For lighting, however, the use of photocontrol receptacles has significantly changed the game. These small gadgets help save energy by automatically adjusting operations based on activity and surrounding natural light levels. In this way, they reduce operational costs and are at the forefront of combating climate change by lowering carbon emissions associated with high power consumption.

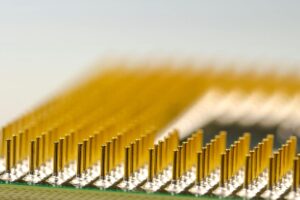

Nevertheless, one of the most important and often underestimated parts of light sensor switches is the contact blade. Available in multiple types and with their most preferred variant of gold-plated contact blades, these small components ensure stable electrical connections, reduce signal interference, and prolong the lifespan of the entire lighting system.

This article will explore why gold plating is essential in 7-pin photocontrol receptacles. We will also highlight its impact on conductivity, durability, and overall performance in demanding outdoor environments.

Purpose of Gold-Plating Contact Blades

Enhanced Conductivity

Gold is renowned for its excellent electrical conductivity, second only to copper and silver. While these two can offer more conductivity in perfect conditions, they are prone to degradation over time much faster compared to gold.

This allows gold-plated contact blades to be sustained even in harsh conditions, making it the best possible option for light photocells. Further, its thermal conductivity also provides effective heat dissipation, avoiding overheating in high-power applications.

Oxidation and Corrosion Resistance

One of gold’s standout properties is its resistance to oxidation and corrosion. Exposed to extreme temperatures, humidity, or corrosive substances such as salt and acid rain, gold does not degrade. Thus, an effective counter against sulfide deposits is yet another prospect of gold plating of contact blades.

Contact Stability

A reliable electrical connection is necessary to ensure the efficiency of smart lighting systems. The ductility of gold allows the formation of smooth, flexible contact surfaces, which withstand the wear and tear from repeated cycles of connection.

Further, in other metals, surface imperfections over time are also an issue of concern. Contrarily, gold remains structurally intact, ensuring minimal signal loss and enhanced contact stability.

Electromagnetic Interference (EMI) Reduction

Electromagnetic interference can disrupt the performance of electronic systems. Due to its non-magnetic characteristics, gold is a suitable material for contact blades since it will not add to EMI.

Advantages of Gold-Plated Contact Blades in Photo Controls

Whether it’s about energy saving potential, extended shelf life, or general working of photocells, gold-plated contact blades have numerous benefits.

Firstly, their high conductivity guarantees efficient power transfer with minimum resistance. This decreases energy losses and enhances the system’s overall performance.

Additionally, since gold does not corrode or oxidize like other metals, it maintains stable electrical contact even under adverse outdoor conditions. As a result of reduced degradation over time, the maintenance and replacement costs remain minimal.

Moreover, gold’s smooth surface reduces contact resistance and wear. This prevents issues like arcing that can damage components. Also, its high durability allows the receptacle to withstand repeated connection cycles without losing conductivity.

Last but not least, gold plating enhances the perceived quality of smart lighting components. This, while increasing the bar for their demand, positions them as high-end, technologically advanced solutions.

By integrating gold-plated contact blades, manufacturers improve the reliability, efficiency, and lifespan of outdoor lighting control systems.

Technical Requirements and Challenges

Optimal Gold Thickness

The use of gold in light sensors is paramount, yet it’s an expensive metal. Thus, appropriate gold plating thickness is critical for striking a balance between durability and cost-effectiveness.

For connectors, a gold layer ranging from 1.27 microns to 2.54 microns is commonly used. This thickness provides sufficient corrosion resistance and wear protection for most applications. To extend the connector’s lifespan further, applying a nickel underplate beneath the gold layer is recommended. This will enhance adhesion and prevent base metal diffusion.

Precision in Electrical Connections

The more resistance there is between connectors, the higher the chances of mechanical failure. So, achieving precise manufacturing tolerances is essential to ensure the proper fit and function of gold-plated connectors.

Advanced manufacturing techniques, such as controlled electroplating processes and meticulous quality control, can be helpful in this regard.

Environmental Adaptability

Whether it is a freezing winter or a melting hot summer, photo sensors have to perform under various environmental conditions. So, selecting appropriate plating is vital to ensure reliable operations.

Gold plating, though, is good to go in both extremes. However, in harsh environments, thicker gold plating or the use of hard gold alloys may be necessary to withstand wear and corrosion. Conversely, in less demanding settings, thinner gold layers can suffice, optimizing material usage and cost.

Future Trends in Gold Plating Technology in Photo Controls

Eco-Friendly Practices

The recent climate change-induced catastrophes have made it necessary to employ eco-friendly practices. The gold plating industry is going well in this direction to reduce its ecological footprint.

Traditional gold extraction and plating processes often involve toxic chemicals like cyanide, posing significant environmental hazards. This has been replaced by innovative approaches, such as using cornstarch instead of cyanide for gold extraction.

Additionally, green synthesis techniques employing natural extracts and biodegradable materials to produce gold nanoparticles are becoming the new norm. This reduces the application of detrimental chemicals and promotes sustainability further.

Nanotechnology Integration

Nanotechnology developments are transforming gold plating by making it possible to apply ultra-thin, nano-scale thick layers of gold. The nano-coatings offer improved electrical conductivity and corrosion protection using less material than traditional methods, thus saving costs.

For example, gold nanoshell development provides greater performance in a wide range of applications, such as electronics and medical devices.

The precise control over coating thickness at the nanoscale allows for tailored properties to meet specific requirements.

Advancements in Manufacturing Precision

The combination of automation and sophisticated manufacturing methods is improving the accuracy and efficiency of gold plating operations. Microfluidic devices, for instance, allow for the controlled production of gold nanoparticles with consistent coating thickness and quality.

These technologies minimize variability, enhance production rates, and allow for the scaling up of intricate plating operations.

Additionally, compliance with standards like ASTM B488 provides a uniform quality and performance in gold electroplating, helping manufacturers achieve the best results.

Cost Reduction Strategies

To make gold plating more accessible, the industry is focusing on process optimization to reduce costs. Employing eco-friendly and efficient synthesis methods lessens the environmental impact and cuts down on material and waste disposal expenses.

Additionally, nano-scale coatings and process improvements, including automation and precise control over plating parameters, further contribute to cost efficiency.

Final Words

Gold-plated contact blades play a crucial role in ensuring the reliability, efficiency, and longevity of photocontrol receptacles. Their superior conductivity, corrosion resistance, and durability make them essential for stable smart lighting systems. For high-quality photocontrol solutions, Chi-Swear is a trusted supplier. Their commitment to innovation and reliability ensures long-lasting performance in outdoor lighting applications.

External Links

- https://en.wikipedia.org/wiki/Electromagnetic_interference

- https://advancedplatingtech.com/gold-plating/gold-plating-thickness-connectors/

- https://news.northwestern.edu/stories/2013/05/making-gold-green-new-non-toxic-method-for-mining-gold

- https://jnanobiotechnology.biomedcentral.com/articles/10.1186/s12951-018-0408-4

- https://en.wikipedia.org/wiki/Nanoshell

- https://www.valencesurfacetech.com/the-news/astm-b488/