Outline

- Introduction

- What Makes PBT the Ideal Material for Outdoor LED Photocell Controller Bases?

- How Does PBT Enhance Safety and Structural Integrity in Harsh Environments?

- Why Is Polypropylene (PP) the Smart Choice for Photocontrol Covers?

- How Does PP Perform Under Weather and Environmental Stress?

- How Do PBT and PP Together Reflect LongJoin’s Engineering Vision?

- What Are the Broader Impacts of These Material Choices on Smart City Infrastructure?

- Final Words

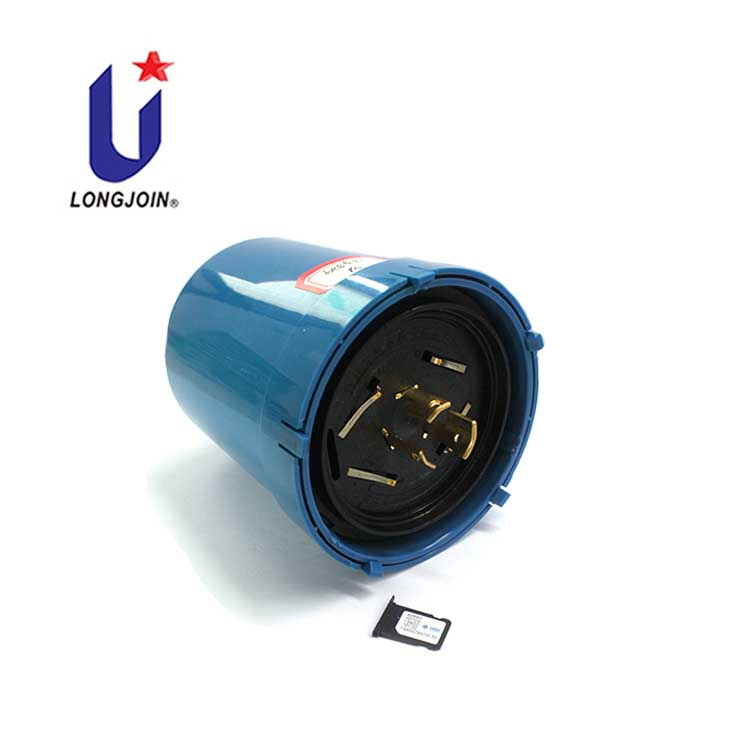

Why does material selection matter in outdoor lighting controllers? Because it affects everything from safety to lifespan. At LongJoin, we don’t choose materials randomly. We use PBT for the base and PP for the cover, and there’s a reason behind each choice.

One provides strength and fire resistance. The other offers flexibility and cost-efficiency. This smart combination helps us build controllers that last, perform reliably, and meet global standards. Let’s break down why we pair these two materials.

What Makes PBT the Ideal Material for Outdoor LED Photocell Controller Bases?

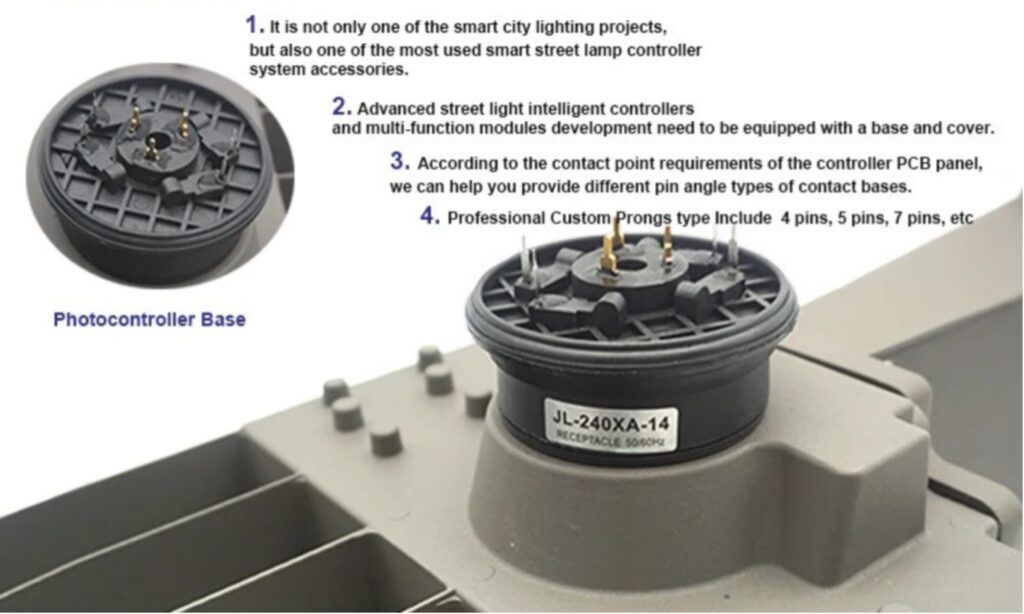

The role of a base is critical for photosensors. It supports the entire product, so it must stay firm in all weather conditions.

LongJoin uses PBT (Polybutylene Terephthalate) to make the base of its street light controllers. Why? Because it’s strong, stable, and built to last in outdoor conditions. PBT keeps its shape and strength even when exposed to tough weather or high temperatures. Here is a comparison of PBT vs other common engineering plastics for outdoor bases.

| Property | PBT (Valox 420SE0) | Nylon 6 | PC (Polycarbonate) | ABS |

| Flame Rating (UL94) | V-0 / 5VA | HB–V2 | V-2 | HB |

| Dimensional Stability | Excellent | Moderate | Moderate | Poor |

| Water Absorption | Low | High | Medium | High |

| UV Resistance | High (f1 rated) | Poor | Moderate | Poor |

| Electrical Insulation | Excellent | Good | Good | Fair |

LongJoin relies on trusted grades like Valox 420SE0. Here are some of its important characteristics:

- It holds a UL ID: E121562.

- It meets fire safety ratings like UL94 V-0 and 5VA.

- It’s also rated for outdoor use — safe around UV, moisture, and heat.

- This means our product is already aligned with international rules like UL, CE, and RoHS.

How Does PBT Enhance Safety and Structural Integrity in Harsh Environments?

UL94 V‑0 & 5VA Fire Resistance

Valox 420SE0 is UL94 V‑0 at ≥0.8 mm and 5VA at ≥2 mm—passing the most stringent UL vertical‑burn tests. It also passes UL glow‑wire tests at 960 °C, ensuring no fire-through or flaming drips. That kind of flame performance is key for outdoor electrical gear.

f1 Rating: UV, Heat & Moisture Resistance

This PBT meets the f1 rating per UL 746C, proving it resists outdoor weathering and water immersion. It holds up in all weather conditions without cracking or degrading. That makes it ideal for streetlight photocell bases.

RTI Over 130 °C: High Thermal Tolerance

Valox 420SE0 shows an RTI ~130–140 °C (electric and mechanical) per UL 746B. It runs safely in high-heat environments without softening. That stability is crucial besides hot LEDs or inside sun-baked enclosures.

Excellent Electrical Insulation

This PBT delivers CTI 175+ (PLC 0) and dielectric strength up to 27 kV/mm in oil. Volume resistivity exceeds 10¹⁵ Ω·cm. That provides robust insulation, preventing arc, tracking, and leakage in high-voltage circuits.

Dimensional Stability for Long-Term Reliability

Its coefficient of thermal expansion is ~1.4×10⁵ cm/cm/°C, and moisture uptake is <0.1%. So, it maintains tight tolerances, especially at socket interfaces. No warping ensures a secure fit over the years.

Here is a table outlining fire safety test outcomes for Valox 420SE0.

| Test Name | Requirement | Result (Valox 420SE0) | Meaning |

| UL94 Vertical Flame Test | V-0 (≤10s flame out) | V-0 Passed | Self-extinguishes quickly |

| UL94 5VA Surface Burn Test | No burn-through in 5 hits | 5VA Passed | Surface resists ignition under stress |

| Glow Wire Ignition (GWI) | >750°C | >850°C | Withstands glowing wire contact |

| RTI (Electrical) | ≥130°C | 140°C | Safe at high operating temps |

Why Is Polypropylene (PP) the Smart Choice for Photocontrol Covers?

The cover’s job is to shield the LED street light photocell’s internals. It doesn’t need the strength of the base. Instead, it protects from dust, light rain, and physical knocks. Polypropylene is the best material for photocell cover manufacturing, and here’s why:

Lightweight & Easy to Install

Polypropylene’s density (~0.90 g/cm³) makes it one of the lightest plastics. This reduces shipping weight and strain during installation. Installers can mount covers quickly and without extra support.

Cost Efficiency & BOM Reduction

PP is among the most economical commodity plastics. It lowers production costs without losing functionality. A lighter, cheaper cover keeps the overall bill of materials optimized. Here is a table comparing material cost and material efficiency.

| Material | Avg. Cost (USD/kg) | Mold Cycle Time | Ideal For | Recyclability |

| PP | $1.20 | Fast (20–30 sec) | Covers, housings, caps | Excellent |

| PC | $2.50 | Moderate | Clear lenses | Moderate |

| PBT | $3.00 | Moderate | Structural components | Fair |

| PVC | $1.60 | Slow | Tubing, insulation | Poor |

Easy Molding & Branding Flexibility

PP forms precisely via injection molding. It allows sleek shapes and consistent wall thickness. Molds can include OEM logos and textures easily. Final parts come out ready for printing or finishing—no extra steps needed.

How Does PP Perform Under Weather and Environmental Stress?

Polypropylene checks all boxes for covers. It complements PBT bases perfectly—offering protection without unnecessary strength or cost. Here are some pointers highlighting its effectiveness under environmental stress.

- Polypropylene resists oils and alkalis. That makes it ideal for coastal or industrial environments.

- It stays stable when exposed to solvents and cleaning agents. This prevents corrosion and swelling.

- With additives like HALS or carbon black, PP withstands sunlight and won’t crack.

- Impact toughness remains strong under moderate weather, and co-polymers give even better resilience.

- PP’s chemical and impact resistance help the full enclosure endure weather cycles. It keeps color and surface finish clean and sharp, even in coastal spray or rain.

- As a molded component, the cover supports visual design and durability.

How Do PBT and PP Together Reflect LongJoin’s Engineering Vision?

LongJoin designs with purpose—PBT delivers structural and safety performance, while PP reduces cost and weight. This smart material pairing optimizes function and budget without compromise.

Each PBT base is UL‑recognized and traces back to Valox UL ID E121562. PP covers are fully compatible with CE and RoHS. Together, both parts meet all international safety and environmental standards.

By pairing UL-certified PBT with durable PP, LongJoin ensures light sensors are safe, certified, cost-effective, traceable, and designed to endure, facilitating reliable smart streetlight deployment in cities worldwide. Here is a table showing LongJoin’s material traceability and certifications for smart lighting projects.

| Material | Certification ID | Regulatory Standard | Traceability Format |

| Valox 420SE0 | UL File: E121562 | UL94, RoHS, CE | Batch-coded, lot traceable |

| PP Resin (Sinopec Y1500) | SGS Reported | RoHS Compliant | Resin origin + MFR lot |

| Final Assembly | CE Marked | EN 60598-1, IEC 61000-6 | Unit serial & QR verified |

What Are the Broader Impacts of These Material Choices on Smart City Infrastructure?

Enabling Safe and Sustainable Smart Lighting Deployments

PBT bases and PP covers meet tough safety standards. This helps cities install photocell sensor LED street lights that are certified and long-lasting. Further, when these LED’s combined with IoT controllers, it help attain low-energy and low-carbon lighting across urban areas.

Reducing Maintenance Costs Through Reliable Materials

These materials reduce failures caused by weather or fire. This means fewer replacements and less downtime. Cities save time and cut costs on repairs and fieldwork.

Supporting Scalable, Modular Product Designs

LongJoin photocell switches are modular, using uniform sockets and snap-on covers. PP molds easily, while PBT maintains its shape. Together, they allow efficient production and scalable designs. This makes upgrades simpler and helps streamline deployment and inventory.

LongJoin’s Role in Accelerating Smart City Transformation

By choosing materials that align with global standards (UL, CE, RoHS), LongJoin empowers municipalities to adopt smart lighting more confidently.

Reliable performance and traceability make it easier to integrate controllers into smart city platforms. This supports cities in building infrastructure that lasts decades with minimal disruption.

Final Words

Smart lighting needs smart materials. PBT and PP offer the right balance of strength, safety, and value. For reliable Long-Join Smart Photocells, Chi-Swear is a trusted partner with proven quality and supply assurance.