Outline

- Introduction

- Why Does Logo Customization Matter in the Photosensor Industry?

- What Are the Available Methods for Logo Printing on Photoelectric Sensors?

- What Are the Pros and Cons of Each Printing Method?

- How To Decide the Best Printing Method for Your Project?

- Why Is Long-Join the Best Partner for Logo Printing on Photo Switch Sensor?

- How Can You Start Branding Your Lighting Control Components Today?

- The Bottom Line

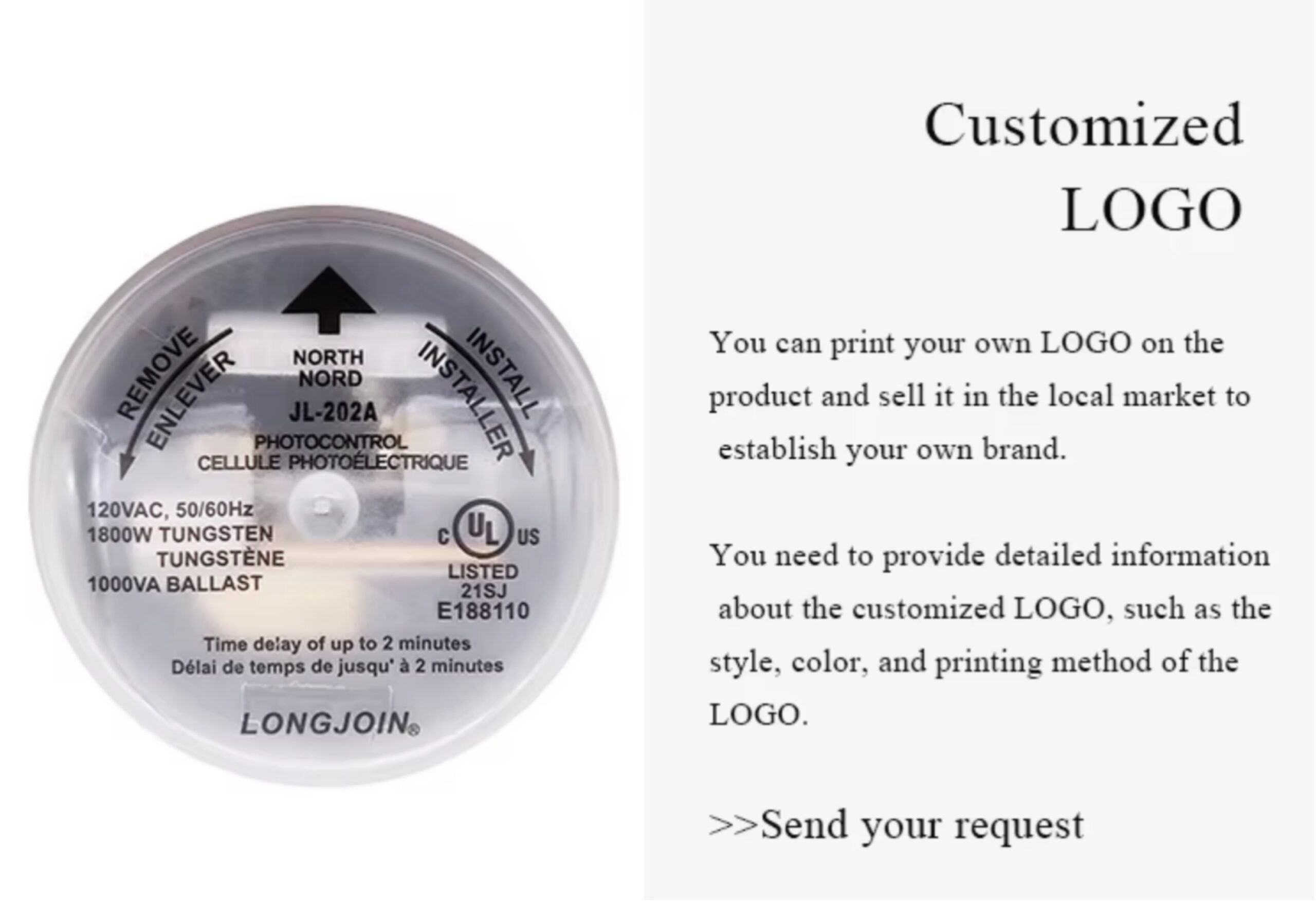

Branding isn’t just about big logos on packaging or ads. In the outdoor lighting industry, even the smallest part speaks for your brand. A photocontroller housing or receptacle with your logo signals trust and technical ownership. It shows clients and cities that you stand behind your product.

But not all printing methods are equal. Choosing the right one makes the difference. This guide breaks it all down—methods, pros, and expert tips.

Why Does Logo Customization Matter in the Photosensor Industry?

Lighting control components aren’t just functional. A branded logo on them speaks volumes. It signals reliability and technical credibility.

Brand Recognition and Trust

- A clear logo helps users and installers identify your brand at a glance. Trusted brands are easier to stock and recommend.

- Consistent branding builds familiarity. Familiarity breeds trust over time.

- In lighting projects for municipalities or distributors, certification and branding on components like housings help meet compliance and provoke confidence.

Professionalism and Ownership

A photocontrol receptacle with a bare housing looks generic. A printed logo changes that. It shows care and ownership. It communicates that you stand behind every unit.

Real-World Visibility

These parts aren’t seen only at installation. They appear on streetlights, control panels, and site checks. An exposed NEMA receptacle or surge-protected base carries your brand on job sites and client installations. That extended visibility reinforces brand presence.

Applications Where It Counts

Logo placement isn’t random. It matters where it’s placed and how it lasts.

- On the photocell switch housings, it’s visible at pole level.

- On NEMA receptacles, it’s seen during inspection or maintenance.

- On surge-protected bases, it’s present at critical safety points.

In each scenario, a clear, permanent logo strengthens your brand’s story. Further, here is a table showcasing why branding is critical for you.

| Factor | With Logo Branding | Without Logo Branding |

| Client Trust | High, shows authenticity | Low, looks generic |

| Product Differentiation | Easy to identify in projects | Hard to distinguish |

| Tender/Project Compliance | Accepted in bids | Often rejected |

| Risk of Counterfeit | Reduced with logos/serials | High |

What Are the Available Methods for Logo Printing on Photoelectric Sensors?

Printing methods vary by material, shape, finish, and durability requirements. Here’s what works in the electronics and lighting parts industry.

Overview of Common Techniques

● Silk Screen

A stencil prints ink through a mesh. Great for bold, low-cost branding on flat surfaces. Durable enough for many outdoor uses.

● Pad Printing

Transfers ink via a silicone pad that conforms to curved or uneven surfaces. Common in electronics for logos on housings and keypads.

● Laser Engraving

Uses a laser to etch into material. No ink, highly durable and precise. Ideal for export-safe, compliance-grade print.

● Heat Transfer

Uses thermal printing onto film, then applies it with heat. Best for colorful, short-run items. Less durable outdoors.

● In-Mold Labeling (IML)

Label applied during molding. The label becomes part of the plastic. Multi-color, highly durable, premium finish.

● UV Inkjet / Digital

Direct digital printing with UV-curable ink. Full-color, gradient-rich designs. Tailored for small batch or detailed artwork.

● Emboss/Deboss (No Ink)

Molded, raised, or recessed logos. Permanent, tactile, and maintenance-free. Excellent for traceability and anti-counterfeit.

Further, here is a comparative table for all these methods.

| Method | Best For | Durability | Visual Quality | Eco-Friendliness | Typical Use Case |

| Silk Screen | Flat plastic or metal | Medium (ink may wear) | Bold, single/multi-color | Moderate (ink required) | Flat housings, side walls |

| Pad Printing | Curved or irregular plastic | Medium | Sharp detail | Moderate | Curved lids, edges of receptacles |

| Laser Engraving | Metal, PC/ABS, PBT | High (permanent) | Monochrome etched look | High (no consumables) | Aluminum bases, export-grade housings |

| Heat Transfer | ABS, PC with flat or gently curved | Medium | Full-color prints | Low (vinyl/ink used) | Decorative covers, short-run branding |

| IML | Injection-moldable plastic | Excellent | Sharp, multi-color | High (in-mold) | High-end receptacles, premium components |

| UV Inkjet | Flat or curved plastic surfaces | Medium–High | Vivid gradients | Moderate–High | Large panels, lid tops needing color precision |

| Emboss/Deboss | Molded plastic parts | Excellent (no fade) | Raised or recessed logo | High (no ink) | OEM base molds, long-term branding |

What Are the Pros and Cons of Each Printing Method?

Silk Screen Printing

Pros

Bright, opaque colors are ideal for flat or lightly curved surfaces. It is durable outdoors. Cost-effective for large runs as the per-unit cost drops significantly.

Cons

- Slow setup; each design/color needs a new screen.

- Fine details are harder to print precisely.

- Uses inks and solvents, which can harm the environment.

Pad Printing

Pros

It adapts to curved and irregular shapes. The initial setup cost is low.

Cons

Less detail and lower durability than laser. It requires specific pads and inks; variable data setups are slow and wasteful.

Laser Engraving

Pros

- Permanent, high-precision marks. This ensures resistance against abrasion, chemicals, and heat.

- No consumables; minimal waste.

- Fast setup; ideal for variable data and automation.

Cons

A high initial cost is needed. Safety requirements are critical. Not suitable for all materials or highly irregular surfaces.

Heat Transfer

Pros

Enables full-color and complex graphics materials like ABS/PC.

Cons

Moderate durability; color may fade outdoors. The process is less eco-friendly.

In-Mold Labeling

- Durable, part of the plastic surface. No ink peel-off.

- Multi-color, high-end appearance.

- Best for volumes high enough to justify mold tooling cost.

UV Inkjet / Digital Printing

Pros

- Instant curing; full-color, high-resolution graphics.

- Less ink waste; rigorous detail reproduction.

Cons

Durability in harsh outdoor conditions may lag. Not optimal for high-wear or frequently washed surfaces.

Emboss / Deboss (No Ink)

Pros

Permanent, tactile branding with no consumables. Excellent longevity, ideal for traceability.

Cons

Limited to injection-molded parts; no color adds visual contrast.

How To Decide the Best Printing Method for Your Project?

The right logo printing method means balancing cost with durability. Here’s a clear guide to help.

Low MOQ Projects (Under ~1,000 Units)

- Silk screen works best for bold, flat logos. Setup costs are higher, but per-unit costs drop fast as volume rises.

- Pad printing suits curved or uneven surfaces. It offers low setup costs and handles multi-color logos in small to medium batches.

- UV inkjet needs almost no setup. It supports full-color detail and fast turnaround—even for single pieces.

Premium or Export-Level Projects

- Laser engraving makes permanent, precise marks. No ink is required. It’s ideal for export-grade durability.

- IML (in-mold labeling) embeds the logo inside the plastic. Clarity is exceptional, and scratch resistance is high.

- Mold engraving or direct molding forms the logo during production. The mark is raised or recessed, so it’s maintenance-free.

Price-Sensitive Clients

- Single-color silk cuts material and time costs sharply.

- Pad printing in bulk reduces per-unit cost significantly for tempo-friendly, tight-margin orders.

City Projects

- IML plus serials strengthen anti-counterfeit ability and meet traceability demands.

- Laser batch IDs offer precision and permanence for batch-level tracking compliance.

Important Considerations

- Evaluate your volume: Low batches → go digital or pad; high batches → consider silk, IML, or molded logos.

- Test outdoor durability needs: Laser and molded logos resist the elements best.

- Check compliance: Export or specs-heavy markets often require ISO, UL standards—laser and IML pass with ease.

- Match aesthetic goals: Multi-color and gradients → UV inkjet or IML. Simple monochrome or textured → molded or laser.

Furthermore, here is a comparison table that analyzes each method based on its cost, durability, and compliance.

| Method | Cost Level | Durability | Compliance Readiness |

| Pad Printing | Low | Medium | Basic |

| IML | High | Excellent | City Bidding Ready |

| Laser Engraving | Mid | High | Export Ready |

| UV Inkjet | Mid–High | Mid–High | Flexible |

| Silk Screen | Low | Medium | Basic |

Why Is Long-Join the Best Partner for Logo Printing on Photo Switch Sensor?

Long-Join leads the field by combining deep technical expertise with strong manufacturing capability. Few suppliers match its balance of compliance, customization, and production efficiency. Here is how it excels:

Proven OEM/ODM Expertise

Long-Join brings over 20 years of OEM/ODM experience. It has delivered solutions to global outdoor lighting brands. This history ensures logo customization meets technical and branding needs without delay.

Integrated Manufacturing Capabilities

Injection molding and logo printing happen under one roof. No outsourcing means fewer risks and shorter lead times. Every logo stays consistent in color, alignment, and durability. Clients gain faster prototyping and stable quality control.

Standards-Ready Compatibility

Each product is engineered for UL773, ANSI C136.10/41, and Zhaga Book 18. Whether for North American utilities or Zhaga-compliant smart cities, logos are applied without affecting safety or compliance.

Flexible Customization Options

Logos are not limited to ink or embossing. Long-Join offers multi-color prints, custom housing colors, QR codes, and anti-counterfeit features. These options boost brand recognition and protect against imitation in crowded markets.

Complete Product Range

Long-Join supports logo printing across its full catalog:

- Twist-lock photocells

- Wire-in controllers

- Zhaga Book 18 sockets

- Surge-protected bases

- Shorting caps

This breadth allows customers to unify branding across all outdoor lighting control points.

How Can You Start Branding Your Lighting Control Components Today?

Getting your logo on street light sensors doesn’t need to be complicated. Long-Join streamlines the process with a fast and flexible approach.

You can request rapid sample runs to check logo placement before moving into mass production. This minimizes risk and ensures brand accuracy from the start.

Whether you need low-MOQ pad printing, UV inkjet for vivid small batches, or IML for high-volume city projects, options are tailored to your scale and market. Each method is matched to cost, compliance, and durability requirements.

From logo design integration to final delivery, Long-Join provides complete OEM/ODM assistance. Clients can combine branding with housing color changes, QR codes, or anti-counterfeit features in a single workflow. All it takes is sending your logo file and application details.

The Bottom Line

Logo customization is more than design. It ensures trust, compliance, and lasting brand visibility in outdoor lighting. Chi-Swear makes this process simple and reliable. Partner with us for Long-Join services and smart photocells that keep your brand in control

External Links

- https://en.wikipedia.org/wiki/Screen_printing

- https://en.wikipedia.org/wiki/Pad_printing

- https://en.wikipedia.org/wiki/Laser_engraving

- https://www.iso.org/home.html

- https://www.ul.com/solutions

- https://www.iec-equipment.com/new/new-31-969.html

- https://www.nema.org/docs/default-source/standards-document-library/ansi-c136-10-2017-contents-and-scope.pdf?sfvrsn=36d2efb_2

- https://www.zhagastandard.org/books/overview/smart-interface-between-outdoor-luminaires-and-sensing-communication-modules-18.html