Outline

- Introduction

- What is the ANSI C136.10 Standard?

- Why Compliance Matters

- Steps to Ensure Compliance

- Familiarize Yourself with the Standard

- Conduct Thorough Testing and Evaluation

- Obtain Certification from Accredited Laboratories

- Implement Necessary Design Modifications (if Needed)

- Challenges and Solutions

- Best Practices for Overcoming Challenges

- Benefits of Compliance

- Final Words

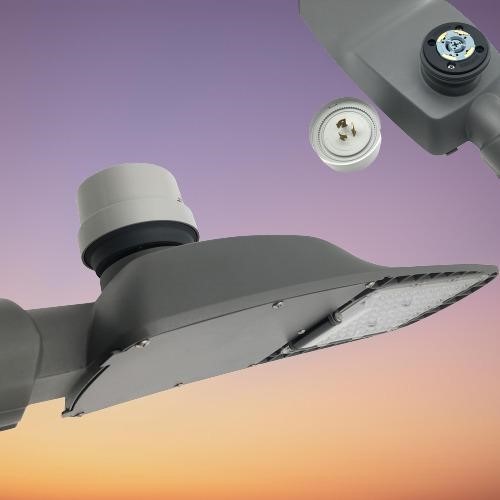

Ever wonder how those streetlights know when to turn on? This Photocontrol is all due to tiny light sensors called photocells! These gadgets play a big role in keeping us safe and saving energy. However, if not adhered to SOP, they might malfunction.

Thus to ensure their smooth functioning, ANSI C136.10 standard comes in. It’s a set of rules that photocell makers and users should follow. Following these guidelines means photocells are safe, reliable, and ready to use.

A lot of people aren’t familiar with the ANSI C136.10 standard. This write-up will expand upon its significance and how it profits both the people who make and the people who use these photocells.

What is the ANSI C136.10 Standard?

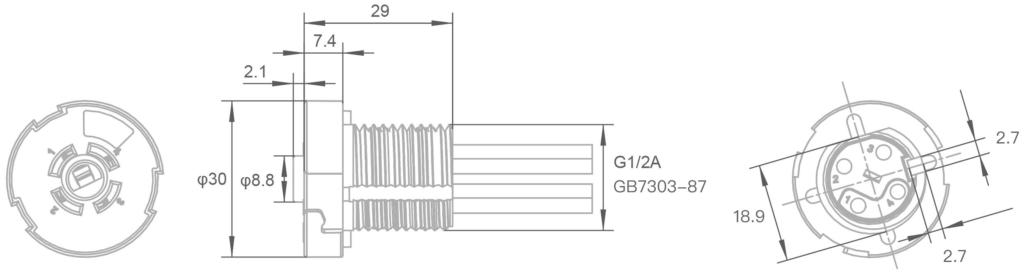

The ANSI C136.10 standard is a set of guidelines developed by the National Electrical Manufacturers Association (NEMA) in the US. It serves as a roadmap to ensure the quality, safety, and performance of button photocells.

The standard covers several key aspects of photocells that include

- Performance Specifications: This includes how sensitive a photocell is to light (sensitivity) and the range of light wavelengths it responds to (spectral response).

- Safety Regulations: The standard outlines safety requirements for materials and electrical components used in photocells to minimize the risk of accidents or malfunctions.

- Testing Procedures: It specifies the methods and equipment used to evaluate a Photo Control Switch compliance with the standard’s performance and safety benchmarks.

Why Compliance Matters

Following the ANSI C136.10 standard is crucial for both manufacturers and users of photocell products. This ensures the photocells are made with safe materials and electrical parts, reducing the chances of fire, electrical shocks, or other hazards.

Compliance also guarantees consistent performance over time. Additionally, the standard promotes compatibility between different photocell brands. This makes replacement easier and ensures that various photocell light sensors will function correctly within a system.

Steps to Ensure Compliance

Following ANSI C136.10 standard build trust with potential customers and get their products accepted in a wider market. For users, compliance means a reliable and secure product, which leads to higher satisfaction and a positive brand image.

Below are steps to ensure compliance.

Familiarize Yourself with the Standard

The first step to ensure compliance is to learn about the ANSI C136.10 standard. This means getting a copy of the document and carefully reading through it. By familiarizing yourself with these details, you’ll know exactly what is expected from a compliant photocell light switch.

Conduct Thorough Testing and Evaluation

Once you’re familiar with the ANSI C136.10 standard, it’s crucial to test and evaluate your photocell products thoroughly.

These tests may assess factors like spectral response, sensitivity, durability under different environmental conditions, and electrical safety. The standard may also specify the necessary equipment to conduct these tests accurately.

Throughout the testing process, meticulous documentation is essential. It’s important to record all test procedures, results, and observations made during testing. This documentation serves as a crucial record to demonstrate compliance with the standard and can be vital during the certification process.

Obtain Certification from Accredited Laboratories

Getting official certification adds more credibility and assurance.

Certification from a recognized lab shows that your photocell products have been carefully evaluated by independent experts and proven to meet the ANSI C136.10 standard.

This certification carries a lot of weight with both manufacturers and consumers, boosting trust and confidence in your product’s safety and performance. Several accredited labs are authorized to test and certify compliance with the ANSI C136.10 standard.

Implement Necessary Design Modifications (if Needed)

Achieving compliance doesn’t have to mean sacrificing product functionality. There may be room for adjustments in material selection, component choices, or even small design tweaks to ensure your photocell performs optimally while meeting the safety and performance benchmarks set by the ANSI C136.10 standard.

The testing process can reveal potential issues like insufficient sensitivity, deviations in spectral response, or electrical components not meeting safety regulations. Understanding these common problems allows you to proactively address them during the design phase for future versions.

Challenges and Solutions

Even experienced manufacturers can face hurdles when trying to comply with the ANSI C136.10 standard. Let’s explore some common challenges and effective solutions.

- Keeping Up with Standard Revisions: The ANSI C136.10 standard is periodically updated. Manufacturers must stay informed about these changes and adapt their testing and production processes to maintain compliance.

- Balancing Cost and Quality: Meeting the standard’s requirements may involve using specialized, and potentially more expensive, materials or components. Manufacturers must find a way to maintain product quality without sacrificing affordability.

- Accessing Qualified Testing Facilities: Finding accredited laboratories with the necessary equipment and expertise to conduct ANSI C136.10 testing can be difficult, especially for smaller manufacturers.

Best Practices for Overcoming Challenges

- Subscribing to industry news or joining relevant professional groups can help manufacturers stay informed about changes to the ANSI C136.10 standard.

- Using value engineering methods can identify alternative materials or parts that meet the standard’s requirements without breaking the bank.

- Building relationships with accredited labs well ahead of time can ensure timely access to testing facilities and expert guidance.

- By addressing these challenges and implementing these strategies, manufacturers can efficiently navigate the compliance process and ensure their photocell control aligns with the high ANSI C136.10 standards.

Benefits of Compliance

ANSI C136.10 guidelines offer many perks for photocell products. Keeping up with this rule lets companies prioritize quality and safety to the full extent during product design and production. This signifies that the photocells produced will be

- Stable and unwavering in their output over the duration, reliably turning on and off light systems.

- Constructed with secure substances and electrical parts, lessening the chance of fire, electricity shock, or other dangers.

Further, by getting ANSI C136.10 certification, manufacturers show that they care about quality and safety. Not following safety standards like ANSI C136.10 can sometimes result in legal issues if a malfunctioning photocell causes accidents or injuries. Noncompliant products may also be subject to recalls, damaging the manufacturer’s reputation and causing significant financial losses.

Final words

In conclusion, adherence to ANSI C136.10 standards is essential for the safety and reliability of photocell products.

Looking for reliable photocell products that meet ANSI C136.10 standards? Consider Chiswear. With their commitment to quality and compliance, Chiswear photocell products offer peace of mind for both manufacturers and users.

One Response

Hey there! Just wanted to say how much I enjoyed reading this post. Your approach to the subject was unique and informative. It’s clear that you put a lot of effort into your writing. Keep up the great work, and I can’t wait to see what else you have in store.