Outline

- Introduction

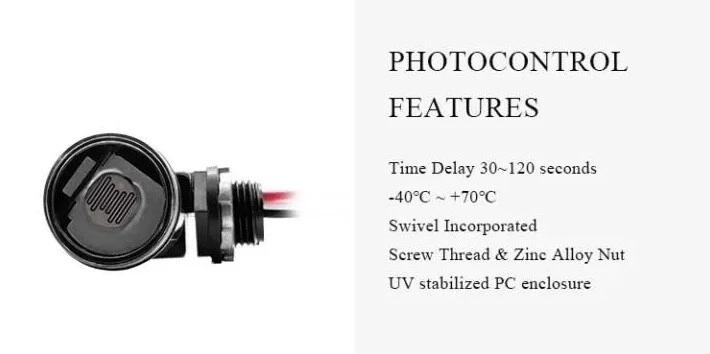

- What Are The Key Elements of Hardware Design Of Photocontrollers?

- How are Photocells Made Environmentally Adaptable?

- How Does the Photocell Help With Energy and Cost Sustainability?

- What To Look for in Maintenance Design When Choosing Photocells?

- What Are Quality Testing Protocols for Photocells?

- Why Longjoin Photocells Are The Best?

- The Bottom Line

Ever wondered why some streetlights keep working smoothly for years while others often fail? Light controllers are the hidden heroes behind them.

They play a pivotal role in modern road and intelligent lighting systems. But what if these controllers aren’t stable? Frequent breakdowns, higher maintenance costs, and disrupted lighting systems follow. Thus, ensuring their reliability means lower maintenance, reduced downtime, and more efficient lighting management.

This guide dives into essential design points to achieve lasting stability, presenting comprehensive solutions by Longjoin Intelligent Technology.

What Are The Key Elements of Hardware Design Of Photocontrollers?

A light controller has an average life span of around 5 to 7 years. This is around 5 times greater than that of an LED light. But what contributes to this much longevity? The secret lies in its hardware design.

Let’s break down the key elements that ensure a boosted lifespan and performance.

High-Quality Component Selection

Reliability is proportional to the quality of components. This is why some photo controllers outperform others in challenging environments.

For example, MOSFETs are high-temperature capacitors. They are designed to work in varied climates from –55°C to +200°C. Thus, they promote efficiency and durability, especially in demanding applications like power factor correction and LED lighting.

Casing Design

You might not know this, but heat dissipation is critical in electronics to ensure optimal functioning. Light sensors achieve this through their casing designs. Another key consideration is the Incorporation of anti-corrosion materials. Applied as coatings, these corrosion inhibitors safeguard internal components from degradation.

Other than the above-discussed parameters, some additional yet important considerations are given in the table below.

| Hardware Element | Technical Aspect |

| EMC Shielding | Use of ferrite bead filters and shielded enclosures to reduce susceptibility to electromagnetic interference. |

| Low-Power Consumption Design | Advanced MCUs minimize power draw while maintaining responsiveness |

| Stable Photosensitive Elements | Use of high-sensitivity photodiodes ensures precise dusk-to-dawn switching |

| Quick-Connect Modular Design | Simplifies installation and replacement through standardized Zhaga/NEMA sockets |

| Real-Time Monitoring Capability | IoT-ready sensors and smart controllers allow adaptive dimming and remote diagnostics. |

How are Photocells Made Environmentally Adaptable?

Photocells are delicate devices. To ensure reliability, they are engineered to withstand a broad temperature spectrum. This involves rigorous high-low temperature cycle testing to validate performance under extreme conditions. For effective moisture and humidity management, IP rating comes into play. This includes waterproofing and applying moisture-proof coatings.

Additional electromagnetic shielding layers are also integrated. They protect against signal disruptions, ensuring consistent operation. These are some of the design strategies that are put in place to enhance the durability and functionality of photo controllers.

How Does the Photocell Help With Energy and Cost Sustainability?

Light pollution, energy waste, and long downtimes are some common issues with traditional lighting. While photo controllers promise to be an ideal solution to counter these issues, the real question is how they do this?

Intelligent Control Design

The secret lies in their technological advancement. Simply put, they integrate smart sensors and management systems like the UM9000. These additions help monitor real-time conditions and adjust illumination accordingly.

Wireless Communication

This cloud integration enables remote control and monitoring of streetlights, ensuring optimal performance and energy efficiency. Such systems also have built-in data recording modules to continuously collect operational data, allowing for predictive maintenance.

Fault Alarms Enhancing Reliability

Going further, the fault alarms enhance reliability by promptly notifying operators of anomalies. This, while reducing downtimes, also curtails maintenance costs.

This fusion of real-time monitoring, data analysis, and early warning systems exemplifies how intelligent control design transforms urban lighting into a proactive and efficient infrastructure.

The table below outlines different aspects of how light sensors help with cost savings and sustainability.

| Aspect | Impact of Photocell Integration |

| Energy Savings | Up to 80% reduction in electricity consumption |

| Environmental Impact | Significant reduction in CO₂ emissions |

| Public Approval | 68% to 90% citizen endorsement rates |

| Failure Rate | Low catastrophic failure rate of around 1% over 6,000 hours |

What To Look for in Maintenance Design When Choosing Photocells?

The easier the maintenance of the lighting control is, the more appealing it will be to consumers. So what are the key aspects that make maintenance convenient?

Some important considerations in this regard are discussed below.

Modular Design

Modular design is simply the inclusion of components that allow for quick replacement of damaged parts without altering the entire system. This reduces downtimes and repair costs.

But the real question here is how to achieve this flexibility, or for consumers, how they can ensure that their chosen light photocell sensor has a modular design. Outlined below are the certifications that ensure the modular design of photocells.

| Certification | Purpose |

| Zhaga Book 18 | Standard for modular, pluggable streetlight controllers |

| ANSI C136.41 | Protocols for dimming receptacles and multi-control nodes |

| DALI-2 | For intelligent lighting control and interoperability |

| UL 773 & UL 773A | Safety standards for plug-in and hardwired photocontrol devices |

Easy Installation

Photocontroller’s compatibility with DIY installations is yet another critical convenience design issue. This effectively facilitates consumers by allowing home debugging. Easy installation also makes it handy to expand lighting systems, quick maintenance, and cost savings.

Remote Upgrade and Maintenance

Over-the-Air or OTA updates allow for the wireless deployment of firmware upgrades to devices within an IoT system. This allows for remote maintenance, which translates into reduced physical interventions and ultimately the cost.

What Are Quality Testing Protocols for Photocells?

Manufacturers employ rigorous testing to guarantee long-term stable operation of light controllers.

But what are these protocols, and how do they mimic real-world conditions?

High and Low Temperature Cycle Testing

In this procedure, devices are exposed to extreme variations in temperature. The primary concern involves ensuring products compatibility with military and aerospace environment demands. MIL-STD-810 is the common standard detailing procedures for such tests

Salt Spray Testing

This is a popular procedure to assess a device’s corrosion resistance. Photo controllers are subject to a saline mist. Compliance with standards like ISO 9227:2012 involves 720 hours of continuous exposure to a 5% atomized mineral salt solution. This verifies the durability of materials and coatings.

Long-Term Continuous Operation Testing

As the name indicates, this involves continuous operations of photocell-integrated lighting fixtures for 48–96 hours. The primary aim of this test is to monitor thermal management and lumen output of lighting systems.

Some other test and their purpose are outlined in the table below.

| Test | Purpose |

| UV Exposure Testing | Examine material degradation under prolonged sun exposure |

| EMI/EMC Testing | Checks resistance to electromagnetic interference |

| IP Testing | Verifies resistance against dust and water ingress |

| Aging Testing | Simulates long-term usage under real-world conditions |

Why Longjoin Photocells Are The Best?

Looking for photo sensors that are easy to install, have a minimalist design, and offer an extended lifespan? LongJoin photocell can end your quest.

Below, we are shedding some light on why they are the go-to solutions.

High-Quality Components

Besides strengthening their own market position, customer satisfaction is the utmost priority of LongJoin. To meet consumer expectations, Longjoin emphasizes strict quality control throughout production. This ensures that each light sensor meets high standards.

Flexibility to Adapt to Various Environments

With an IP rating of 65 or above, Longjoin’s light controllers are resistant to extreme temperatures, rain, dust, and humidity. Their robust construction ensures reliable performance year-round. This gets a slew of benefits in terms of reduced maintenance needs, cost savings, and effective urban lighting management.

Modular and Standardized Interfaces

Utilizing NEMA standard interfaces, Longjoin’s light controllers offer plug-and-play installation and easy maintenance. This modularity allows for straightforward upgrades and ensures compatibility with various lighting systems. Ultimately, the logistical challenges are pre-empted and extra costs are saved.

Intelligent Control and Remote Management

Integrating IoT communication technology, Longjoin’s controllers enable both local autonomous control and adaptive cloud-based remote management. The self-developed UM9900 intelligent light pole management system facilitates intelligent, refined, and data-driven adaptive lighting solutions.

Here is a table comparing LongJoin Vs other photocells.

| Feature | Longjoin Photocells | Standard Photocells |

| Operating Voltage | Broad range of 105- 305VAC | Typically limited to 120-277VAC |

| Power Consumption | Optimized at 1.5VA | Often higher, leading to increased operational costs. |

| Load Capacity | Supports up to 1000W Tungsten and 1800VA Ballast | Generally supports lower loads, limiting application scope |

| Response Time | A 3-10 second time delay to prevent false triggering | May lack adequate delay mechanisms |

| Environmental Adaptability | Operates effectively in temperatures ranging from -40°C to +70°C with up to 99% relative humidity | Often have narrower operational ranges |

The Bottom Line

Longjoin light controllers stand out for their durability, intelligent control, and seamless adaptability to various environments. For those seeking a trusted supplier, Chi-Swear offers genuine Longjoin products with expert support, making it a dependable choice for high-performance lighting solutions.