Outline

- Introduction

- Importance of Photocell Controllers in Outdoor Lighting Systems

- Overview of the Need for Testing and Fault Handling

- Photocell Controller Lifespan Testing

- Key Factors Influencing Lifespan of Photocell Controllers

- Handling Faults: Shutoff and Turn-On Scenarios

- Fault Shutoff

- Fault Turn-On

- Benefits and Drawbacks of Each Fault Handling Method

- Fault Shutoff

- Benefits

- Drawbacks

- Fault Turn-On

- Benefits

- Drawbacks

- Choosing the Right Method

- Fault Shutoff

- Case Studies: The Power of Testing and Fault Handling

- Conclusion

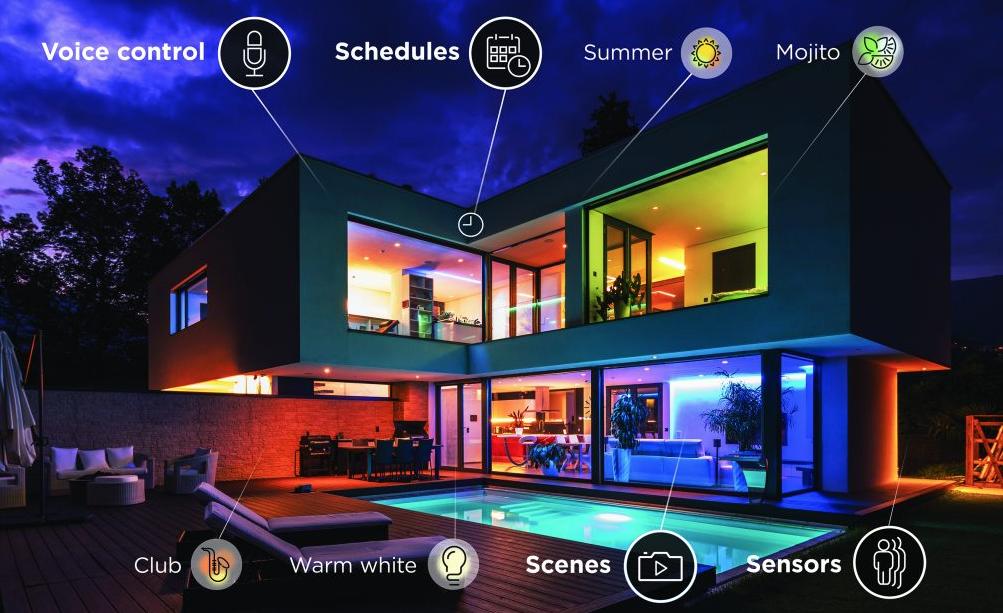

Outdoor lighting systems play a significant role in today’s energy-efficient world. An unsung hero supporting all these fixtures is the photocell controller, which adjusts the lighting automatically by detecting the ambient light levels. This means that it ensures the lights get switched on when the sunlight goes down and switches off when the sunlight comes up to avoid energy wastage and money loss.

The actual consideration when looking at the effectiveness of an outdoor lighting system is the period over which a photocell controller works. A fails-to-fail controller disrupts system functionality, demands replacement with additional costs, and presents maintenance headaches.

This details details effective testing and fault-handling practices that can be utilized to maximize the life of your photocell controllers. Further, we will provide proactive testing of the devices and an understanding of fault responses to give you high performance, long life, and the resultant sustainability of the lighting solution.

Importance of Photocell Controllers in Outdoor Lighting Systems

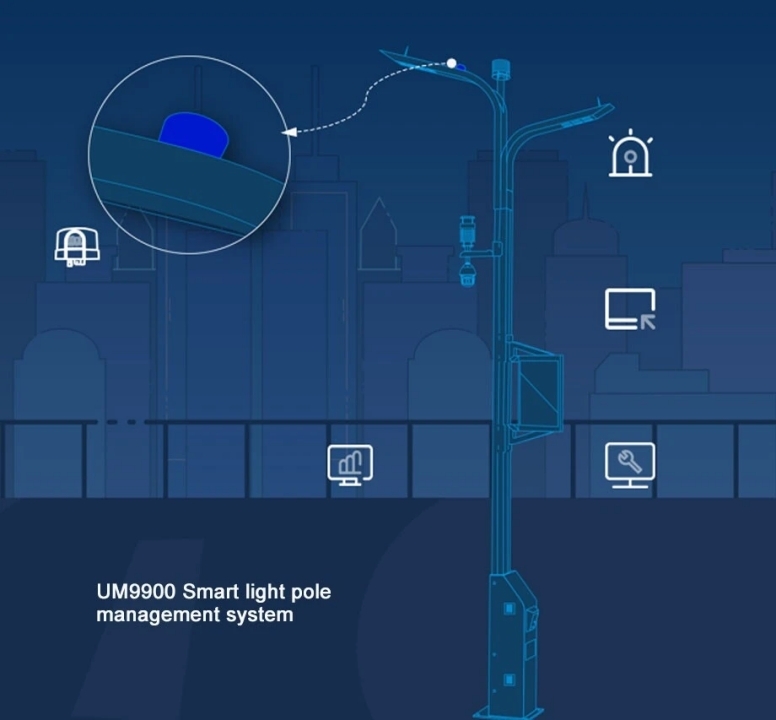

Photocells are vital parts of today’s modern outdoor lighting systems. They help in automatically turning lights on at dusk and off at dawn. This functionality delivers several key benefits.

- The intelligent control of the unit tremendously reduces power use and reduces electricity costs and environmental impact.

- Photocell controllers eliminate manual operation, ensuring the lights are on whenever needed, especially in outdoor areas that are hard to reach.

- They make walking safer at night for pedestrians and drivers because the lamps illuminate paths and entranceways as soon as it gets dark.

- Due to photocell controls, lighting loads can even be used to act as a deterrent by switching on in response to ambient light.

The short of it is that the lighting systems are optimized by these devices, which would enable homes or businesses to save energy while providing convenience, safety, and security without any hassle and in an automated manner.

Overview of the Need for Testing and Fault Handling

While photocell controllers offer significant benefits, ensuring their optimal performance and longevity requires proactive measures. Regular testing helps identify potential issues before they cause disruptions. This can involve simulating real-world conditions to assess their functionality and durability.

Additionally, understanding how controllers handle faults, such as sudden light fluctuations or power outages, is crucial. Implementing appropriate fault-handling strategies can minimize disruptions and ensure timely system recovery, preventing unnecessary downtime and maximizing the overall effectiveness of your outdoor lighting system.

Photocell Controller Lifespan Testing

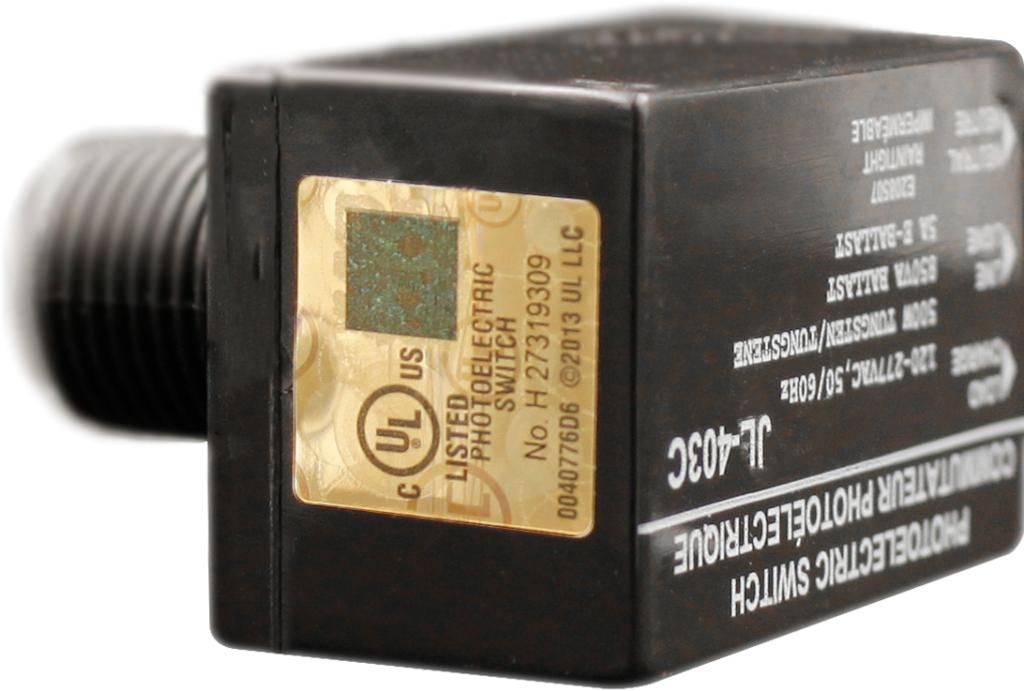

Manufacturers ensure photocell controllers meet their expected lifespan by subjecting them to a set of stresses typical of the actual operating conditions expected to be seen in practice. Such tests usually include:

- Temperature Cycling: Controllers are exposed to several cycles of extreme high and low temperatures that efficiently replicate harsh weather conditions or seasonal changes.

- Humidity Exposure: Subject them to high humidity with high moisture for long hours to check their resistance to moisture and possible corrosion.

- Electrical Stress Testing: Controllers are subjected to a simulation of power surges and possible voltage fluctuation to see their performance when electrical disturbances attack.

These tests must be done according to the norms fixed by the industry—for example, Underwriters Laboratories or the International Electrotechnical Commission. These standards define specific parameters of the tests, which allow for repeatability and reproducibility, regardless of the manufacturer.

Key Factors Influencing Lifespan of Photocell Controllers

Although standard life span testing can provide a baseline for how long controllers will last, several real-world factors can influence how long controllers will last.

Controllers made with high-quality materials, like Chiswer products, generally last significantly longer. They usually include lead-free photocells and reliable relays. Typically, severe temperatures, significant humidity, or corrosive elements can break down components and cause components to wear out faster. A controller rated for temperate areas has the potential to fail in short order in a sweltering desert.

Further, routine voltage surges degrade the internal circuitry over time, causing eventually shortened life expectancy. Even with some surge-protected controllers, a direct lightning strike can cause the device to fail catastrophically. The testing of photocells gives a window into how photocells are expected to perform under ideal test conditions.

In reality, however, when the device is used in real life, for example, when used in a coastal area with high humidity and frequent thunderstorms, the controller may have a shorter life expectancy than in the more sustainable environment.

Handling Faults: Shutoff and Turn-On Scenarios

Photocell controllers can encounter various faults during operation, such as sudden light fluctuations or power outages. These faults can disrupt the system’s functionality if not handled appropriately. Two main approaches exist for fault handling in photocell controllers:

Fault Shutoff

In this scenario, upon detecting a fault, the controller prioritizes safety by shutting off the lights completely. This ensures no unintended or unsafe lighting activation during the fault condition.

Fault Turn-On

This approach prioritizes maintaining illumination. If a fault occurs, the controller may attempt to turn the lights on, even if the ambient light levels suggest otherwise. This can be beneficial in situations where temporary light disruptions are undesirable.

Benefits and Drawbacks of Each Fault Handling Method

Both fault shutoff and fault turn-on approaches offer distinct advantages and disadvantages, making the ideal choice dependent on the specific application:

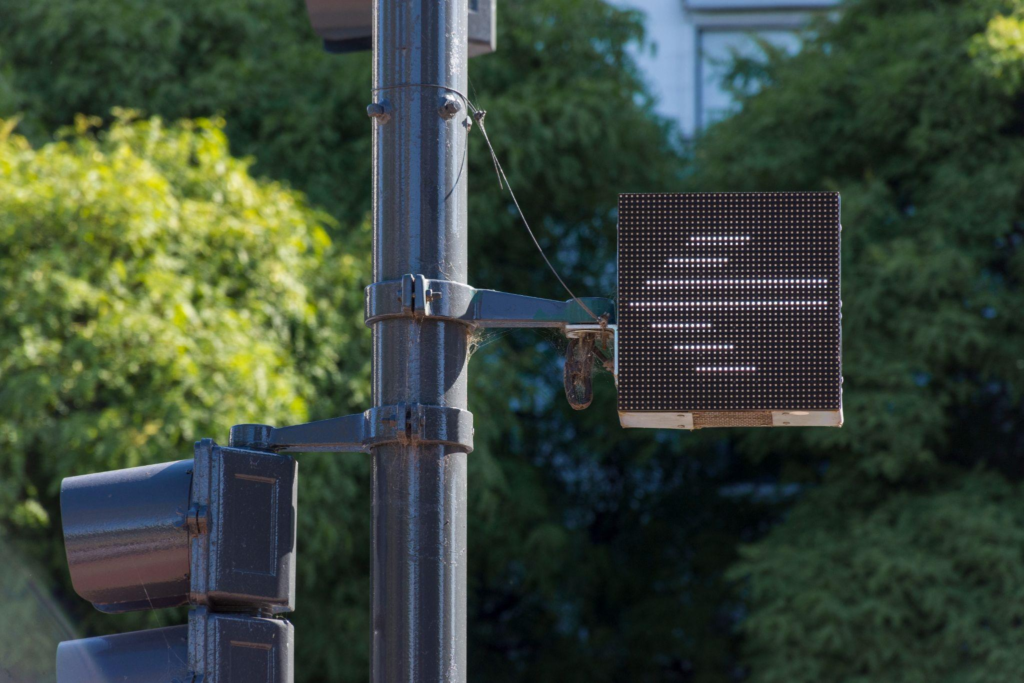

Fault Shutoff

Benefits

- Prioritizes safety by preventing unintended light activation during faults.

- Useful in areas where unexpected illumination could be hazardous (e.g., near traffic signals).

- Minimizes potential damage to the lighting system from electrical faults.

Drawbacks

- It can cause temporary darkness during power outages or light fluctuations, potentially impacting safety or security.

- It may not be ideal for areas requiring continuous illumination, even during faults.

Fault Turn-On

Benefits

- Maintains illumination during faults, minimizing disruptions in areas requiring constant light, e.g., building entrances and security lighting.

- Enhances user experience by avoiding sudden darkness.

Drawbacks

- Lights may be activated unnecessarily during faults caused by temporary light fluctuations, e.g., passing headlights.

- Increases potential risk of electrical issues if the fault is related to power surges.

Choosing the Right Method

Selecting the appropriate fault-handling method depends on factors like the application’s specific needs, safety considerations, and the surrounding environment. For instance, fault shutoff might be preferable for traffic signals, while fault turn-on could be more suitable for building security lighting.

Case Studies: The Power of Testing and Fault Handling

Real-world examples illustrate the importance of robust testing and well-chosen fault-handling strategies in maximizing photocell controller lifespan and system effectiveness.

Imagine a project involving photocell controllers for a string of solar-powered streetlights in a remote desert location. The manufacturer’s lifespan testing data indicates a 10-year life expectancy. However, the extreme desert heat and occasional sandstorms pose unique challenges. Here’s how testing and fault handling can play a role:

- Testing: The controllers should undergo rigorous high-temperature testing exceeding typical desert conditions. This ensures they can withstand the heat without component failure.

- Fault Handling: Fault shutoff might be the preferred strategy. During sandstorms, sudden changes in light levels could be misinterpreted as dusk. Shutoff prevents unnecessary light activation and potential damage from sand accumulation on the photocell.

Conclusion

Maximizing the lifespan of photocell controllers requires regular testing, effective fault handling, and adherence to best practices. Implementing these strategies not only ensures optimal performance but also enhances cost efficiency and sustainability. For reliable and long-lasting photocell controllers, consider Chiswear photocells, which are known for their durability and superior quality.