Article Outline:

- I. Introduction

- II. Photocell Basics

- III. OEM vs. ODM

- IV. Key Photocell Specifications:

- V. Precision and Accuracy

- VI. Durability and Longevity

- VII. Conclusion

Photocells from Original Equipment Manufacturers (OEM) and Original Design Manufacturers (ODM) play an essential role in various industries, ensuring efficient and reliable control of lighting systems. These components are critical for outdoor lighting solutions because they provide automated control based on ambient light conditions. In this post, we will look at the specs of OEM/ODM photocells and their important characteristics and advantages.

Photocell Fundamentals

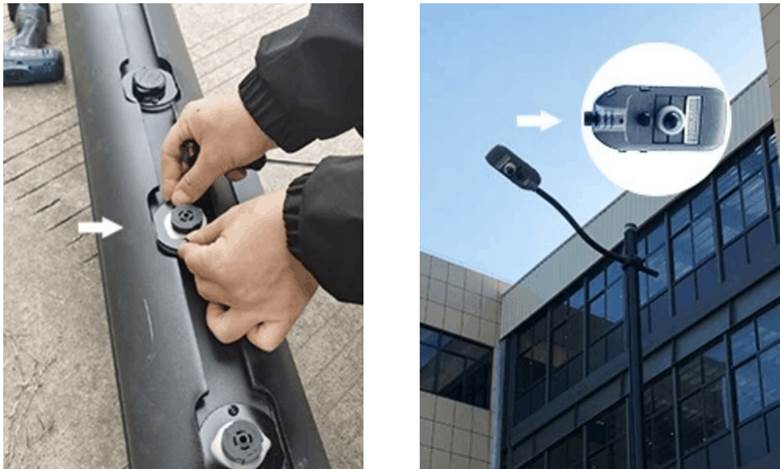

Photocells, also known as photoresistors or light-dependent resistors (LDRs), are devices that vary their resistance in response to light exposure. OEM/ODM photocells are explicitly built for integration into lighting systems, allowing for automated lighting management based on natural light levels.

OEM versus ODM

OEM Photocells: These are photocells manufactured by one business and sold to another, incorporating the photocell into their finished product. In the case of OEM photocells, companies buy these light-sensitive devices to integrate them effortlessly into their lighting fixtures or systems.

ODM Photocells: A manufacturer designs and manufactures the entire product, including the photocell, which is then branded by another firm. This enables firms to tailor the product to their specifications without interfering with manufacturing.

Key Photocell Parameters

Sensitivity Range: OEM/ODM photocells have a sensitivity range that specifies the spectrum of light intensities to which the photocell will respond. This is critical for adapting the lighting system to the environment’s specific needs.

Response Time: A photocell’s response time refers to how rapidly it can adjust to changes in ambient light. Faster response times are vital in applications that require rapid adjustments to changing lighting conditions.

Operating Temperature: Photocells must work consistently throughout a wide temperature range. The operating temperature parameter guarantees that the photocell stays functional in various environments.

Accuracy and Precision

Precision: The ability of OEM/ODM photocells to regularly and precisely measure light levels determines their accuracy. Photocells with high precision ensure that the lighting system responds consistently to variations in ambient light.

Accuracy: The ability of a photocell to deliver a reading that nearly correlates to the actual light level is referred to as its accuracy. Photocells that are accurate prevent excessive illumination adjustments and contribute to energy savings.

Longevity and Durability

Weather Resistance: Photocells resistant to adverse weather conditions are required for outdoor lighting systems. Weather-resistant photocells ensure the total lighting solution’s lifespan and dependability.

Life Expectancy: OEM/ODM photocells have a set life expectancy, which indicates how long they are expected to function well. Longer life expectancies result in lower maintenance costs and higher overall system reliability.

Conclusion

OEM/ODM photocells are critical components in modern lighting systems, offering automated control and increasing energy efficiency. Understanding essential features such as sensitivity range, response time, operating temperature, precision, accuracy, weather resistance, and life expectancy is critical when choosing the proper photocell for a particular application. These parameters will likely evolve as technology advances, resulting in even more efficient and dependable photocell solutions.

INTERNAL LINKS:

- https://chi-swear.com/

- https://chi-swear.com/zhage-photocell-series/

- https://chi-swear.com/product/jl-224bk-photocell-light-sensor-omnidirectional-face-top-sensor-for-european-market/

- https://chi-swear.com/main-introduction-of-photocell/

- https://chi-swear.com/about/

- https://chi-swear.com/smart-iot-lighting-control-system/

EXTERNAL LINKS:

One Response

You’ve provided such a unique perspective. I appreciate your thoughts on this!