Outline

- Introduction

- What Is Power Consumption in Lighting Controls and Why Does It Matter?

- Where Does Power Consumption Come From in Photoelectric Sensors?

- Why Should Cities and Operators Care About Controller Power Usage?

- What Do Real-World Case Studies Reveal About Energy Savings?

- How Can You Choose the Right Low-Power Photo Switch Sensor?

- What Is the Bottom Line on Hidden Energy Costs in Lighting Controllers?

- Final Words

Outdoor lighting depends on photocell controllers to switch lights on and off automatically. But have you ever thought about the energy these controllers use themselves?

Even small standby loads can add up when thousands of units are installed across a city. Higher power drains solar batteries faster, ultimately reducing efficiency and increasing costs. That’s why low-power photosensors are becoming a smart choice. They cut hidden energy waste, save money, and extend system lifespan.

What Is Power Consumption in Lighting Controls and Why Does It Matter?

Photocontrols detect ambient light and switch lighting loads accordingly during dusk and dawn. They serve as the brain of a dusk-to-dawn lighting system. But the controller itself isn’t “free” in energy.

Role of Photocell Switches in Dusk-to-Dawn Lighting

Light sensor photocell switches monitor light levels continuously. When darkness falls below a threshold, they trigger the light to turn on. When daylight returns, they shut it off. This automation avoids reliance on timers or manual switches. It adjusts in real time to seasonal and weather changes.

The Often-Overlooked Energy Usage of the Controller Itself

While most focus on the lamp’s power draw, the controller draws power even when idle (standby/monitoring mode). Some older or simpler models consume 0.1 W to 0.3 W in sensing mode.

In more complex or “smart” controllers with wireless modules, this standby usage can rise to 1–3 W. Even that small draw, multiplied by thousands of units and continuous 24/7 operation, becomes meaningful.

The table below shows the hidden energy cost of standby power in controllers.

| Standby Power (W) | Extra Energy Used per Year (kWh) | Added Annual Cost (at $0.12/kWh) |

| 0.5W | 4.4 kWh | $0.53 |

| 1.0W | 8.8 kWh | $1.06 |

| 2.0W | 17.5 kWh | $2.11 |

| 3.0W | 26.3 kWh | $3.16 |

How Controller Consumption Impacts Overall System Performance

- In grid-connected systems, controller standby power increases utility costs and erodes savings from efficient LEDs.

- In solar off-grid systems, the controller draws on battery reserves, reducing available energy for the lamp itself.

- In smart lighting networks, continuous communication or sensor polling requires always-on electronics, making low standby power even more critical for scalability.

- Over long system lifetimes, the accumulated “hidden” energy cost of controllers may rival or exceed wiring losses or control inefficiencies.

Where Does Power Consumption Come From in Photoelectric Sensors?

Even when “doing nothing,” a photocell controller draws energy. Here is an outline of the typical power consumption ranges of standard vs smart models.

| Controller Type | Standby / Idle Draw | Additional Load from Comms / Switching |

| Basic photocell (non-smart) | 0.1 W – 0.3 W | Minimal (just switching the circuit) |

| Enhanced photocell (analogue + delay logic) | ~0.3 W – 0.8 W | Some internal logic overhead |

| Smart controller (LoRa / ZigBee, etc.) | 0.5 W – 1.5 W+ | Up to 1–3 W extra during active comms |

| All-in-one smart lamp controller | < 3 W total (incl. comms) | — |

To understand how this works, let’s break it down into its main power sinks:

Internal Control Circuitry (Standby / Sensing Mode)

The controller’s microcontroller, voltage regulators, and light sensor (photodiode or LDR + ADC) must remain active to monitor ambient light. This constant, subtle draw is called standby power.

Lower-end outdoor light sensor switches often stay below 0.3 W in sensing mode, but more feature-rich controllers can draw 0.5 W or more. For instance, many simple photoelectric switches list ~0.6 W maximum power consumption in idle states.

Relay or Transistor Switching Current

When the controller activates or deactivates the lighting circuit, it must switch current through a relay, MOSFET, or solid-state transistor. During this switching and for holding states (contacts energized), there is a power loss:

- Relays have coil current losses

- Transistors incur conduction and gate-drive losses

- Inrush current when driving inductive/LED loads adds extra transient draw

These switching currents are small relative to the lamp, but not negligible in long-duration systems.

Communication Modules in Smart Controllers

Controllers with wireless modules require additional power. Even in idle or “sleep” modes, the communication hardware must remain partly active for wake-ups, polling, or synchronization.

LoRa-based sensors, for example, are designed for ultra-low power with average current consumption in sleep of around 100 nA, but awake/Tx currents can reach tens of milliamps. Smart controllers often stay semi-active to listen for network messages.

Some smart lamp controllers specify overall consumption “< 3 W” in normal operation, including communication modules.

Why Should Cities and Operators Care About Controller Power Usage?

When a city installs thousands of streetlights, the controller’s energy draw becomes a hidden expense. Even 0.5 W extra per unit adds up to significant kilowatt-hours and costs across a municipality.

City Roadway Lighting

Suppose a city has 10,000 lamps and each controller uses 0.5 W more than an optimized version. That means an extra 5,000 W running continuously. Over a full year, that extra draw equals ~43,800 kWh, which at municipal energy rates is a nontrivial utility bill.

In large retrofits, energy managers aim to shave every watt. The controller’s idle power is often one of the first targets for reduction.

Solar Street Lamps

In off-grid solar systems, every watt consumed by the controller reduces what’s available to power the LED at night. A controller with 1 W idle load might consume ~12 Wh overnight. That’s the lost capacity the lamp can’t use. The over time impacts include:

- Battery cycles increase

- Depth of discharge worsens

- Battery lifespan shortens

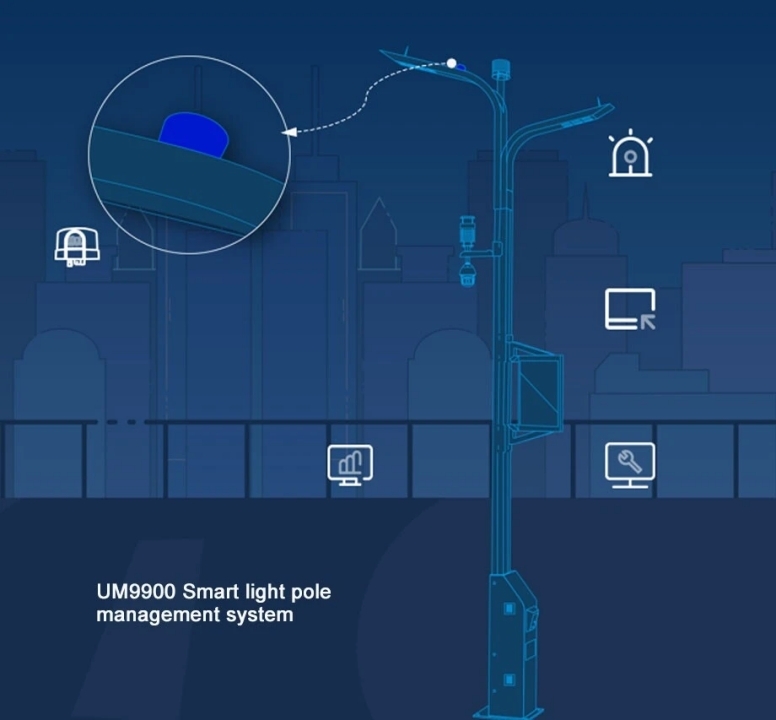

Smart Lighting Networks

Smart lighting systems typically keep communication modules (LoRa, ZigBee, NB-IoT) partially active to listen for commands or report status. That idle or “listening” state consumes power—even when nothing is happening.

To make a smart network efficient, the “always-on” cost of controllers must be minimized.

What Do Real-World Case Studies Reveal About Energy Savings?

Real projects show small controller savings scale into large financial and operational gains. Below are two concrete examples drawn from product specs and field studies.

Case 1 — How Did a Chinese Municipal Retrofit Save Over ¥100,000 Annually

A municipal retrofit replaced an imported dusk-to-dawn photocell sensor, averaging 1.8 W idle, with Long-Join JL-243 units averaging 0.8 W. The JL-243 is a dimming photocontrol widely used in large streetlight projects.

Simple annual savings math:

- Units: 30,000

- Per unit standby reduction: 1.0 W (1.8 − 0.8)

- 12 Night hours × 365 days

- Energy saved = 30,000 × 1 W × 12 × 365 / 1000 = 131,400 kWh/year

- At ¥0.8/kWh, annual saving ≈ ¥105,120 (~$14.5k). (Calculation verified.)

Case 2 — How Did African Solar Street Lights Gain ~10% More Battery Efficiency

Off-grid solar systems lose usable energy to controller idle draw. Field studies and performance reports show that controller standby power shortens nightly lighting hours and increases battery cycling.

Project details (typical):

- Original controller idle: 1.0 W.

- Replacement: Long-Join JL-240 (spec’d as low-draw receptacle/controller with built-in delay/shorting features).

- Net standby reduction: 0.5 W (1.0 − 0.5).

- For a single lamp operating with limited battery capacity, that 0.5 W saves ≈ 6 Wh/night (0.5 W × 12 h).

- Across seasonal cloudy periods, that headroom can translate into ~10% more usable lighting time and fewer deep discharge cycles.

Key Takeaways from Both Cases

- Small per-unit standby cuts multiply quickly in large fleets.

- In grid cities, energy and bill savings are immediate and measurable.

- In off-grid systems, reduced standby load improves autonomy and battery longevity.

- Product selection (JL-243, JL-240) should consider both electrical specs and on-board features like delay/shorting caps and surge protection to maximize real-world gains.

How Can You Choose the Right Low-Power Photo Switch Sensor?

When selecting a light photocell sensor, every detail matters. The right design choices can dramatically lower “invisible” energy waste. Here is the key selection criteria and best practices.

Power Rating (< 1 W standby)

Use models whose idle power draw is under 1 W. Anything higher means your “waste” is creeping up. In large-scale installs, that extra watt becomes many kWh annually.

Switching Circuit Optimization

Look for features like zero-cross switching (turning on/off when the AC waveform crosses zero) to reduce inrush stress. Also prefer designs with relay hold optimization or low-hold current coils to minimize power when contacts stay engaged.

Smart Features

If the controller supports wireless communications, ensure it has a sleep mode where modules turn off or enter deep-sleep when idle. Active time should be minimized. The controller should wake only when needed (dusk, network command, etc.).

Certification Requirements

Ensure the controller has recognized certifications:

- UL / cUL ensures safety compliance in North America.

- CE / EMC covers European safety & electromagnetic standards.

- DOE / IES verifies efficiency and performance compliance if required in your region.

- ANSI C136.10 / C136.41 are industry standards for photcontrol devices and dimming/integration performance.

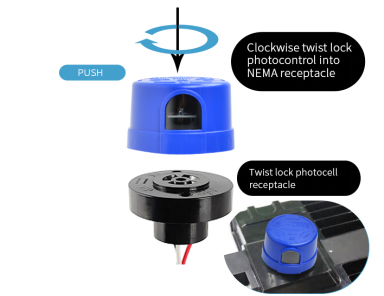

For example, Long-Join’s JL-240 series twist-lock receptacles are cRUus certified under UL file E188110 and conform to ANSI C136.41 standards.

What Is the Bottom Line on Hidden Energy Costs in Lighting Controllers?

Controllers may seem minor compared to lamps, but their hidden energy draw can erode savings—and you can no longer afford to ignore them.

Include Controllers in Energy-Saving Strategy

Most energy projects focus on efficient LEDs, wiring, and smart dimming. But leaving the controller’s idle load unchecked is like leaving a faucet running. It’s a steady drain that accumulates over time and scales.

Benefits Beyond LEDs

By cutting controller waste, you achieve:

- Lower utility bills in grid-powered systems

- Extended battery life and more runtime in solar or off-grid systems

- Reduced maintenance burden as systems run cooler, fewer failures, less stress

Recommended Controllers for Optimized Performance

For real-world deployment with energy savings built in, consider Long-Join’s JL-240, JL-243, and JL-245 series. These are engineered with:

- Low idle draw

- Dimming and delay/shorting features

- Certified compliance with industry standards

- Integration readiness for smart lighting networks

Here is a table outlining the performance of LongJoin low-power models.

| Model | Standby Power | Key Feature | Ideal Application |

| JL-240 | 0.5W | Delay + shorting cap | Solar street lights |

| JL-243 | 0.8W | Relay hold design | City retrofits |

| JL-245 | <1W | Smart sleep/wake | Large-scale smart grids |

Final Words

Low-power controllers cut hidden energy costs and extend system life. Real-world results prove the savings are significant. For trusted performance, Chi-Swear supplies LongJoin smart photocontrollers that meet global standards. A reliable choice for any upgrade.