Outline

- Introduction

- Dual-Layer Protection Design

- Advantages

- Disadvantages

- Adding UV-Resistant Particles

- Advantages

- Disadvantages

- Comprehensive Analysis and Recommendations

- Application Scenarios

- Cost and Process

- Product Lifespan

- Final Words

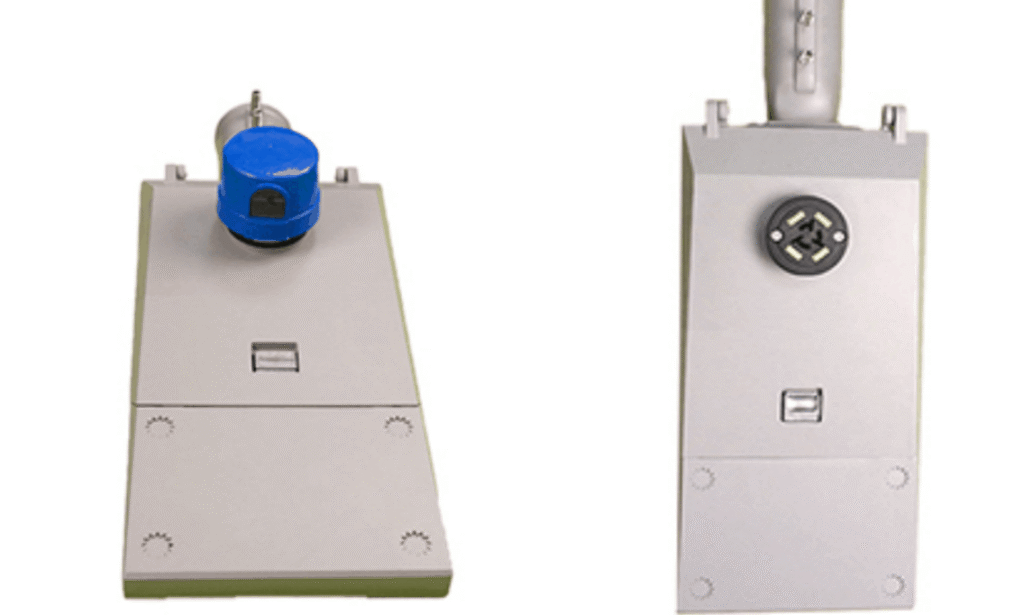

Outdoor photocontrol receptacles, often exposed to prolonged sunlight, face significant degradation from UV rays, which can weaken their enclosures, leading to cracking, fading, and loss of structural integrity.

This deterioration can result in malfunctions or frequent replacements, driving up maintenance costs and reducing system reliability. As a result, incorporating UV-resistant strategies into the enclosure design is crucial for extending product lifespan and ensuring consistent performance in varying environmental conditions.

This article will comprehensively explore two primary UV-resistant approaches in outdoor photocontrol receptacle enclosure design: dual-layer protection and the integration of UV-resistant particles.

Dual-Layer Protection Design

In outdoor photocontrol receptacles, an additional external coating or outer material layer is designed specifically to shield against direct UV exposure, often referred to as a dual-layer protection design.

This typically consists of UV-resistant polymers or specialty coatings that absorb or deflect harmful rays, preventing them from penetrating the primary enclosure material. By creating a physical barrier, this design reduces UV-driven molecular breakdown in the underlying layer, preserving the enclosure’s strength and functionality over time, especially in regions with high sun exposure.

Advantages

Dual-layer protection significantly enhances durability by minimizing UV-induced degradation, which is particularly beneficial for applications in high-exposure environments.

The protective layer also contributes to overall enclosure aesthetics by maintaining color and appearance, which can be critical for installations where visual consistency matters.

Additionally, this method offers prolonged performance, reducing the frequency of maintenance and replacement and thereby lowering lifecycle costs despite the higher initial investment.

Disadvantages

The addition of a dual-layer protective design introduces increased material and manufacturing costs due to the specialized components and processes required. It can also complicate production, as precise application is needed to ensure uniform protection across the entire enclosure surface.

Furthermore, the extra layer adds weight, which could affect installation ease and compatibility with certain mounting systems. In applications where weight and cost constraints are critical, this approach may be less feasible.

Adding UV-Resistant Particles

UV radiations can pose significant threats to the overall durability of photocontrols. Thus, incorporating UV-resistant particles, such as UV absorbers or stabilizers, into the material mix offers an effective shield. These particles act at a molecular level and absorb or dissipate UV energy. This ultimately prevents the degradation of the polymer chains within the receptacle material.

Common additives include benzotriazole, benzophenone, and hindered amine light stabilizers. These materials are dispersed throughout the base material during production. By integrating these stabilizers directly into the polymer, manufacturers can provide UV resistance without altering the receptacle’s appearance or primary physical properties.

Advantages

Adding UV-resistant particles is generally more cost-effective than applying a dual-layer coating, as it reduces the need for additional production steps. This method preserves the core material’s flexibility and structural properties since it doesn’t require changes to the photocontrol receptacle’s thickness or weight.

Additionally, the process is simpler and compatible with standard manufacturing practices, allowing for efficient, large-scale production. Receptacles treated with UV-resistant particles benefit from moderate UV protection that extends product lifespan in environments with lower to moderate UV exposure.

Disadvantages

However, the UV resistance provided by particles alone is limited compared to dual-layer coatings, making them less effective in extremely high-UV environments. A challenge with this approach is achieving an even distribution of the particles, as uneven mixing can lead to inconsistent UV protection across different areas of the enclosure.

Furthermore, while effective initially, some UV stabilizers may degrade over time, reducing their protective abilities and raising questions about long-term durability under continuous UV exposure.

Comprehensive Analysis and Recommendations

Application Scenarios

Dual-layer protection is the optimal choice for outdoor photocontrol receptacles in regions such as desert climates or high-altitude areas where UV intensity is significantly higher. The dual-layer design, with its dedicated protective coating, ensures an extended barrier that mitigates the impact of UV rays on the core material, effectively reducing cracking, fading, and structural weakness.

This level of protection is crucial for installations with demanding durability standards and extended replacement intervals, as it maintains both the aesthetic and mechanical integrity of receptacles exposed to harsh sunlight over time.

Cost and Process

For projects where cost management is essential, particularly in areas with moderate UV exposure, adding UV-resistant particles offers a practical solution. This method provides a reasonable level of UV resistance without the added expenses associated with dual-layer production.

It maintains the material’s flexibility and original weight, supporting easy integration into standard manufacturing workflows.

Although the protection level is not as robust as dual-layer coatings, particle integration effectively shields the enclosure in environments where UV intensity is not extreme, ensuring an economical yet sufficient approach to UV protection.

Product Lifespan

For receptacles requiring prolonged durability and minimal degradation, a combined approach using both dual-layer protection and UV-resistant particles is recommended. This hybrid method leverages the surface protection of the dual layer with the internal reinforcement provided by UV stabilizers within the material, creating a multi-tier defense against UV damage.

This strategy maximizes the product lifespan, especially in regions with variable but intense sunlight exposure, ensuring that enclosures remain functional and visually intact across extended usage periods. Combining these strategies offers a comprehensive solution where both resilience and reliability are top priorities.

Final Words

Incorporating UV-resistant strategies like dual-layer protection and UV-stabilizing particles is essential for extending the durability and functionality of outdoor photocontrol receptacles. For reliable, high-performance photocontrols that meet rigorous UV resistance standards, Chi-Swear offers expertly designed solutions tailored to withstand demanding environmental conditions.